The manufacturing industry is constantly changing. With adaptations to reduce carbon footprints and advancements in technology, the sector is continuously tested and expected to keep up with these changes. Often, it’s the employer’s responsibility to ensure that their workers have the latest relevant training.

That is why, in today’s blog, we’re looking into the benefits of upskilling your workforce. First, we will explore what upskilling is and discuss the various advantages this process can bring to your employees and your company.

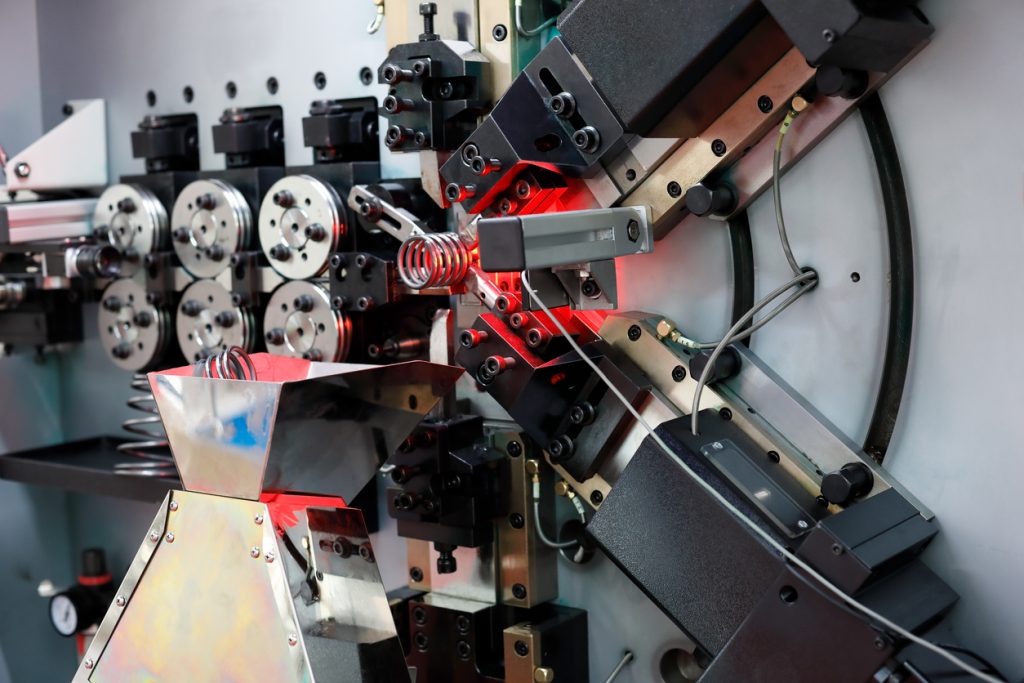

As leading spring manufacturers in the UK, we have a plethora of knowledge on upskilling within the manufacturing industry. We are proud to have worked with and alongside many apprentices over the years, providing them with the skills and experience they needed to have a successful career in engineering and manufacturing. To learn more and discover how you can get involved with European Springs, please don’t hesitate to get in touch – we are always more than happy to offer our assistance and expert advice.

What Is Upskilling?

First of all, it’s essential to understand what upskilling means. At first glance, some may believe it is the idea of basic training, but it’s much more than that.

Upskilling is essentially continuous learning, not just an occasional training course, for example. Workplaces will provide various training programs and offer a choice of development opportunities to widen their employees’ abilities and reduce skill gaps. Often, an upskilling strategy is put in place to improve the skills required by employees to complete their current job and expand their skill sets, allowing them to advance in their roles. Additionally, this will enable them to move around the company and take on new challenges. In recent times, employers have utilised upskilling to close the digital gap and ensure that employees are up to speed with the latest technology in the manufacturing field.

Some examples of upskilling include but are not limited to:

- Formal education such as degrees and apprenticeship schemes

- Internal mentoring and shadowing programs

- Virtual or online courses

Let’s take a look at some of the benefits of upskilling.

Skills and Service Development

Of course, the main benefit of upskilling is that your employees will get the chance to develop their skills. This is great for everyone involved – workers get to learn something new and employers cultivate a workforce that is up-to-date with the latest training and ready to take on the next challenge. In addition, through upskilling, your employees will come to understand that the manufacturing industry is everchanging. By continuously upskilling your workers, you’re teaching them to be aware of adaptions to their working day in line with technology upgrades and industry standards.

Employee Motivation

Another fantastic benefit of upskilling is the motivation it will give your employees. Through upskilling, you engage your workers and encourage them to excel in their current role whilst potentially offering them other opportunities in the company. When an employee feels demotivated and stuck in their position, unable to see where it leads them, they are much more likely to leave the company. By upskilling and ensuring they have plenty of opportunities, there is a much higher chance of employee loyalty, meaning they will remain with the company for longer. Motivated and happy employees are more likely to enjoy their job, so as their employer, you must be doing what you can to guarantee this.

Increased Productivity

It shouldn’t come as a surprise that upskilling leads to increased productivity in the workplace. As employees are happy, motivated, and satisfied with their role, they are more likely to succeed. This, of course, directly affects the company’s overall productivity and triumph.

By gaining knowledge, skills, and experience in multiple areas, they will become more confident and complete given tasks successfully and to a higher standard. Additionally, these extra skills learnt through training mean less time is spent researching and learning in the long term. If a specific task needs some training, implementing upskilling for the entire workforce will benefit you as the employer. Everyone will then have the knowledge and skills required to complete the task. And more time available means a more productive workforce.

Customer Satisfaction

When we look at the benefits explained above, it is clear that each one leads to customer satisfaction. If your workforce has a team of employees with a high and developed skillset, there is a higher chance they will be able to satisfy your customer’s needs. If your employees are happy and motivated, they will offer better customer service than workers who are unsatisfied with their job and demotivated by their lack of opportunities. A productive workforce means tasks will be completed quickly and to a high standard, which is fantastic for customers.

There is no better time than now to begin upskilling your team. We hope this blog has been helpful, but these are only some of the benefits on a long list of reasons to develop your employee’s skills and services. To stay updated with the latest industry news, please head over to our blog, where we post regular content for industry professionals, apprentices, customers, and clients. It is an excellent resource for anyone interested in learning more about the fascinating and ever-changing world of manufacturing. Finally, please feel free to contact us with any questions about our spring manufacturer services including tension springs, torsion springs and die springs, and ask for our advice on upskilling your company.