Why Stainless Steel is the Ideal Material for Corrosion-Resistant Springs and Pressings

Corrosion resistance is a vital consideration for many when choosing the correct material for applications where springs are exposed to moisture, humidity or other corrosive elements. Among the available options, stainless steel stands out as a top choice due to its excellent anti-corrosive properties, impressive tensile strength, and long-lasting durability.

As spring manufacturers, we understand the importance of choosing the right material for your application. In this blog, we’ll explore why stainless steel is an ideal choice for corrosion-resistant springs and pressings, how it compares to other commonly used materials, and the applications where it truly excels. Whether you need guidance on material selection or insights into stainless steel’s unique advantages, we’re here to help.

Why is Stainless Steel Suited for Corrosion Resistance?

Stainless steel is a form of iron alloy that can contain other metals such as nickel, titanium, copper, and others. The key feature that differentiates stainless steel from regular steel is its resistance to corrosion, typically because of its higher chromium content. For an iron alloy to be classified as stainless steel, it must contain at least 10.5% chromium, but most variations of stainless steel contain more than this. In comparison, regular steel contains around 10% chromium.

The high chromium content creates an oxide layer on the surface of the steel, protecting it against oxidation and other effects of environmental exposure. This oxide layer is self-healing, so that if the surface is damaged in any way, the chromium in the steel reacts with the oxygen in the environment to form a new protective layer. The nickel within stainless steel also helps protect it against reducing atmospheres and certain acids such as phosphoric.

The properties of stainless steel can be altered by adjusting the percentages of its make-up, allowing us to provide stainless steel springs and pressings that are particularly adapted to certain purposes. In addition to its corrosion resistance, stainless steel is often favoured because of its durability and high yield strength. Moreover, stainless steel keeps its structure and shape under extremely hot or cold conditions, making it a strong solution that can stand the test of time, and this is why it is used in things like cutlery.

Stainless Steel Versus Other Corrosion-Resistant Materials

While stainless steel is often chosen for its corrosion resistance, it’s not the only spring material on offer that provides this quality. Other metals, including titanium and its alloys, phosphor bronze and some nickel-copper alloys, are considered in the selection of a corrosion-resistant spring material. Titanium, for example, is also resistant to corrosion and offers a lightweight solution where weight is a consideration, but it comes at a higher cost than stainless steel. Equally, springs and pressings made from nickel-copper alloys have an excellent resistance to corrosion caused by acids, alkaline solutions, and seawater but also come at a higher price point and are not as widely available for large-scale productions.

We offer a variety of stainless steel alloys for spring and pressing manufacturing. These include regular stainless steel, stainless steels specifically designed for anti-corrosion, stainless steel for high temperatures, and non-magnetic stainless steel. The type of stainless steel chosen will depend on the application, and, therefore, must be carefully chosen to perfectly suit your requirements.

Stainless Steel Spring and Pressing Applications

As one of the most common spring materials, stainless springs have a wide variety of applications within different industries.

The most common types of springs that stainless steel can be found in are compression springs and torsion springs. Compression springs are one of the most versatile spring types and are particularly popular in the automotive, pulp and paper, and railway industries. They are also frequently found in oil rigs, medical devices, and aeronautics – where compression springs are used in aircraft engines, guidance systems, and turbines. Compression springs also exist in plenty of everyday items, such as watches, phones, pens, and cars.

Pressings can also be made using stainless steel, as it not only offers a sleek aesthetic appearance but does not deteriorate like other coated steels when exposed to wet and damp environments. They are frequently found in areas where hygiene is a must, such as hospitals and dental surgeries, due to their ability to maintain sterile environments.

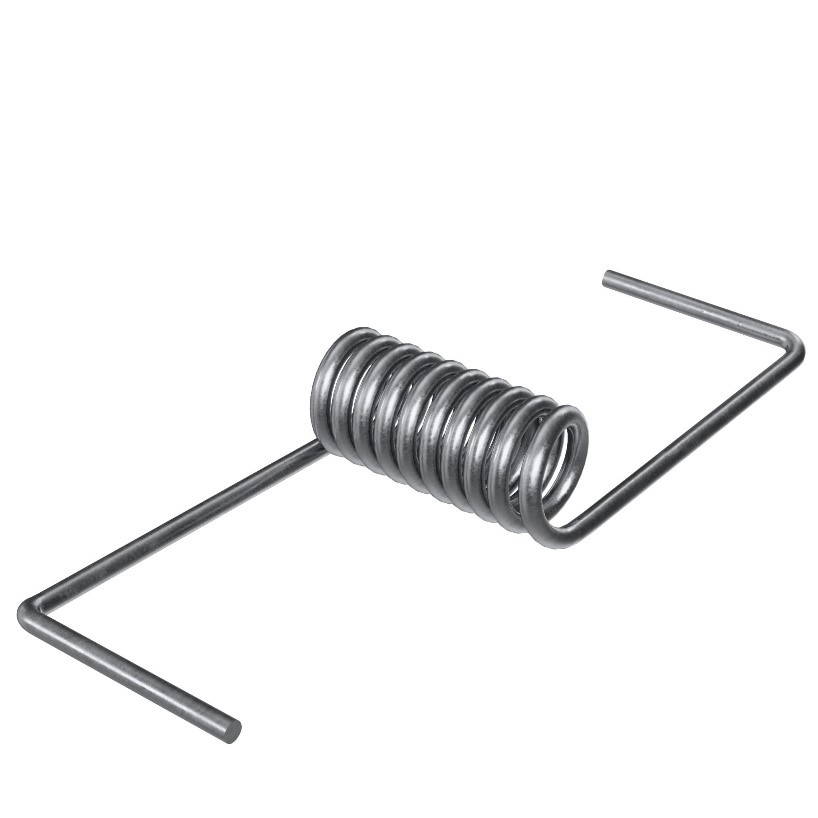

Torsion springs often utilise stainless steel because of its strength and durability. This allows torsion springs to experience high levels of repeated stress and strain in environments of elevated humidity and moisture, ultimately making the springs last longer. Torsion springs are found in garage doors, clocks, watches, and various automotive applications where they withstand high temperatures and corrosive environments.

Stainless steel springs are frequently used in the marine industry, where resistance to corrosion is a key concern. Some variations of stainless steel, such as 300 series stainless steel, have a higher chromium percentage of up to 25%, making them excellent for marine construction, including bridges, harbours, and ports. Variants of this material, like Stainless Steel Type 316, have a lower carbon content and a higher molybdenum content and are most suited to medical and hygiene applications where sterilisation is essential.

European Springs and Pressings’ Expertise in Stainless Steel Spring Manufacturing

At European Springs and Pressings, we are experts in manufacturing high-quality stainless-steel springs and pressings. Choose from the range of springs we offer or create your own custom spring to meet your set of exact specifications and dimensions. If you need any guidance on selecting the right spring material for your application, then feel free to contact us.