Specification of the Bruderer BSTA 500-110B

The Bruderer BSTA 500-110B is said to be one of the world’s most advanced high-speed precision presses. It is an amazing piece of machinery, as it is able to produce between 100 and 1120 stampings per minute. But this is one amazing aspect of the machine out of many. The Bruderer BSTA 500-110B is operated through a press control that is governed by a computer. This, along with a touch screen interface, offers the operator a logic overview of all process data that is relevant.

Because of the unique lever system of the Bruderer BSTA 500-110B, it means that the load from the stamping operation is distributed through the mechanism. This means that, along with a precise mass counterbalancing system, the absolute minimum clearances in all bearing and oil lubrication play very important roles in the maintenance, high precision and long life of the machine.

Has It Changed The Manufacturing Process?

The Bruderer BSTA 500-110B provides a larger press bed area, which has a size of 1080 x 650 mm, allowing for multi-progression tooling of complex processes and manufacturing procedures. As well as this, one of the main benefits of this machine is that, because of its high precision construction, it offers reduced die wear on all springs and even high tensile spring quality materials. This is great for European Springs, as all springs will be made quickly and will maintain an extremely high quality.

The computerised control system reduces the set-up time of manufacturing, meaning that it shortens the time to market on new spring products and also improves efficiency on small volume production batches. With the technology developed by Bruderer, this press machine is able to produce springs incredibly quickly and of extremely high quality. So, does this mean that European Springs is going through the start of a new era in spring manufacturing?

Has European Springs Changed As A Company?

The introduction of the Bruderer BSTA 500-110B press has definitely paid off and it has shaped European Springs as a company. In 2016 alone, because of the Bruderer investment, European Springs has grown by a factor of 10% and has also created 35 new jobs. Across the European Spring sites in London, Cornwall and Leeds, sales have increased by £16m and the workforce has increased to 170 employees.

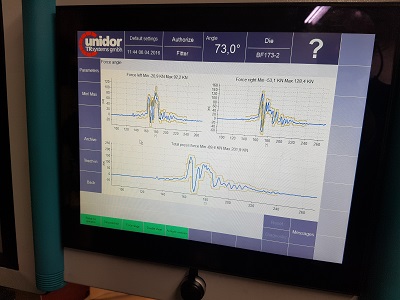

Because of the company’s expertise, European Springs were able to collaborate with Bruderer to make slight modifications to the existing 500-110B machine. These additions include an acoustic sound booth and press monitoring technology. The implementation of these is guaranteed to extend the life of the press and increase machine productivity.

Because of the amount of success that the Bruderer BSTA 500-110B press has brought to European Springs, Bruderer has been commissioned to complete a full refurbishment and update of our Finzer multi-side machine that we use to manufacture strip and wire components.

So, just after the middle of 2016, the Bruderer BSTA 500-110B machine press has settled in nicely in the European Springs family and it has definitely benefitted the company and its workforce. But who knows what the future has to hold in the spring manufacturing industry?

If you would like to know more about anything with regards to our equipment, then please don’t hesitate to contact us. Just give us a call on 0208 663 1800 and one of our friendly members of staff will be more than happy to help.