Here at European Springs, we have over seven decades of experience designing, manufacturing, and implementing our springs in various sectors. As a result, we produce an impressive stock catalogue of springs and are familiar with every type, including the unlimited scope of custom and bespoke springs. This enables us to work closely with all industries, providing our expertise and high-quality products to the masses.

However, this world may seem complicated and somewhat daunting for those not in the spring manufacturing industry. So to shed some light on the importance of the sector, we’re exploring everything you need to know about springs in physics. We’re taking it back to basics by exploring the definition of a spring, the history of its design, the importance of spring durability, and so much more. Read on to learn about the fascinating past of springs and how we at European Springs use this knowledge to assist us in manufacturing high-quality, durable products for a wide range of industries.

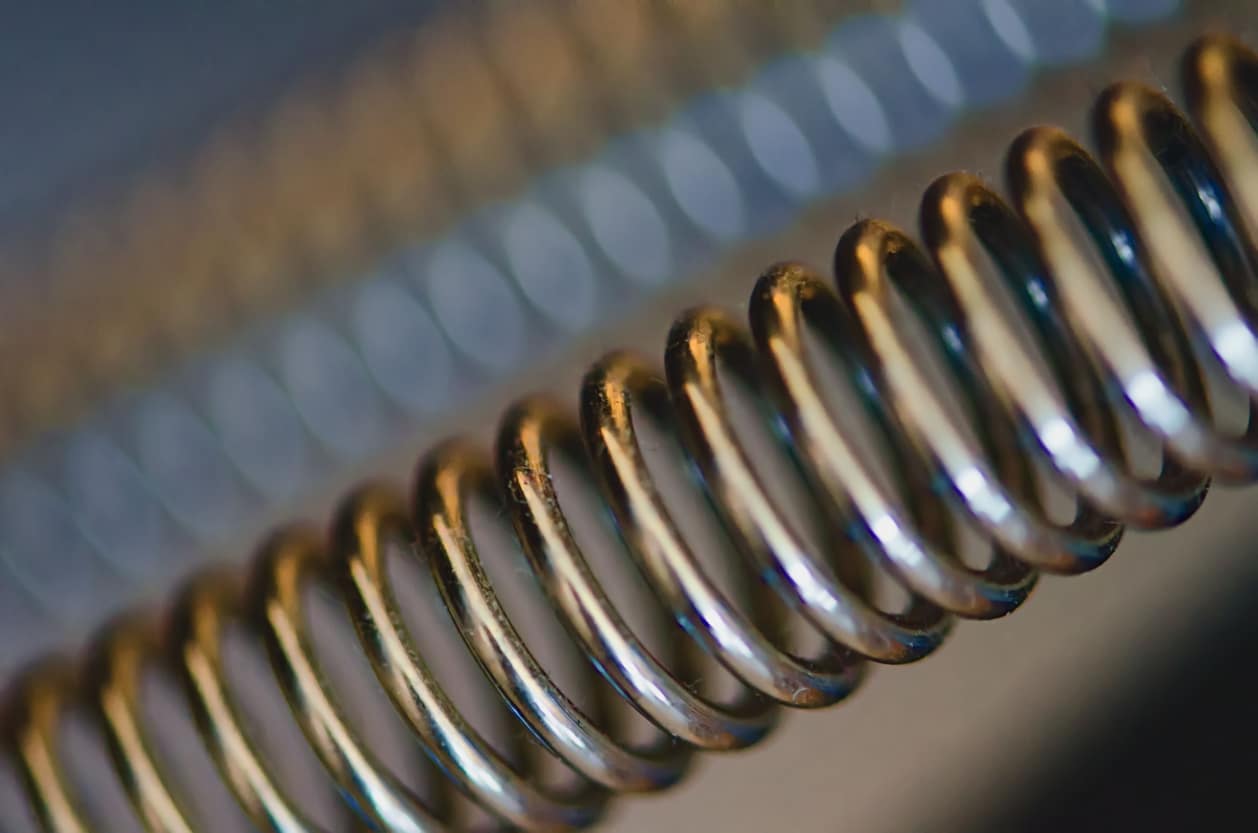

What Are Springs?

Before we delve into the physics behind spring design, let’s take a look into what a spring actually is. There are many different wordings of the definition of a spring. Essentially, a spring is a flexible object that can store and exert force and mechanical energy simultaneously when subjected to force. While doing so, it deforms in shape before returning to its original form when the force has been removed.

Springs come in an extensive range of forms, including:

- Compression springs

- Torsion springs

- Suspension springs

- Wave springs

- And so many more.

Each of these spring types provides the user with a list of benefits and capabilities suited to a different use. As a result, the use of springs is almost endless. They can be found in practically every industry, from farming and agricultural machinery to the medical sector and everything in between.

How Were Springs Invented?

Springs have been in use throughout human history, with some of the first recorded examples in use within the bow and arrow. From there, developments occurred globally, with the spring going from strength to strength and incorporating itself into a range of objects, such as tweezers.

It wasn’t until the late 15th century that the first coiled spring was documented. This documentation of use included springs in door locks and spring-powered clocks. The latter led to the implementation of springs within watch design, a manufacturing practice still in use today.

However, it was Robert Hooke who propelled the use of springs in 1676 with Hooke’s Law.

All About Hooke’s Law

In 1676, English scientist, mathematician and architect Robert Hooke made a discovery that would forever change springs in physics. In simple terms, his idea was that the more a spring is deformed, the more force is needed to further deform it. He noticed this when looking into the stress vs strain curve and how for many materials, they have a linear region.

When stretching a metal spring, the force required to deform it is directly proportional to the spring’s extension. In algebraic terms, this is written:

F = -kX

F is force, k is spring constant, and x is the deformation or extension length.

Of course, like with every rule, there are exceptions. For example, if a spring is stretched too far, it will not conform to Hooke’s Law, and when this happens, the measurements are taken, and this length is considered the elastic limit.

The Spring Constant

To further understand the importance of Hooke’s Law, let’s dive into the k within the formula, otherwise known as the spring constant.

This part of the equation refers to the exact force needed to deform a spring. For example, if you want a stronger spring, the spring constant must be high; the lower it is, the weaker the spring.

Various factors come into determining the spring factors, such as:

- The diameter of the wire and the coil

- The material used to manufacture the spring

- The length of the spring when relaxed

- The number of coils

Once you have determined this, you can work out what needs to be done to achieve your ideal spring constant for the usage of your spring.

Where Does Spring Physics Come Into Spring Design and Manufacture

As leading spring manufacturers, we understand that physics plays a significant part in the design and manufacturing of springs. Understanding Hooke’s Law, the spring constant, and the other physical elements of a spring allow you to customise a spring to your exact specifications, which is precisely what we do here at European Springs.

It’s essential for our designers and manufacturers to know how a spring will behave in different circumstances. For example, durability is crucial for many of our clients who need their springs to handle a significant amount of force. We know that in order to strengthen a spring, thus making it more durable, we need to increase the spring constant.

A lot of the time, these things can’t be estimated and instead require precise numbers in order to get the desired result. Our experienced and knowledgeable engineers have been specially trained to ensure that the best results are achieved for every single spring designed and manufactured here at European Springs.

We are proud to produce an extensive range of specialised springs with this knowledge and can provide bespoke springs to your exact specifications considering the physics detailed above.