Wearable technologies are electronic devices designed to be worn on the body, serving a variety of purposes, including training, education, and monitoring health, wellness, and fitness. Wrist-worn devices, such as smartwatches and fitness bracelets, are the most common type of wearables. However, the market also offers a wide range of alternatives, including smart glasses, headbands, belts, clothing, and footwear.

The growing recognition of wearable technology for applications such as patient monitoring is particularly noteworthy.

Currently, wearables are most commonly purchased by individuals who already lead a healthy lifestyle and wish to track their progress.

The Importance of Engineering for Precision, Reliability and Performance

Although traditional electronic materials are rigid, structural engineering advancements have led to the development of soft electronic materials that can conform to the complex shapes of the human body. This skin-like flexibility significantly enhances signal integrity and minimises motion artefacts. Additionally, improved mechanical flexibility allows for the creation of highly sensitive sensors for measuring physical parameters.

Comfort is also a key consideration in the design of wearable devices, as it directly influences a user’s willingness to wear them. For instance, some individuals avoid wearing watches or rings due to discomfort. Therefore, precision engineering approaches must be developed to enhance wearability and ensure a seamless user experience.

At European Springs and Pressings, we have produced and assembled headband assemblies for a range of sectors, including defence and health and safety. We have also made pressed straps for prison inmates to wear around their ankles, and components for battery contacts in sensory straps and watches.

Key Components in Wearable Technologies

So, how are springs and pressings employed in wearable technologies? The integration of springs offers a set of design challenges. However, the role of springs in enhancing the functionality, comfort and durability of wearables is set to extend. Springs carry out significant roles in wearables; they contract to accumulate energy and expand to release it to stimulate movement and support. Springs are utilised in various wearables to enhance performance.

Medical Wearables and How They Enhance Patient Care

Wearable medical device technology is revolutionising health care in multiple ways. It allows persistent monitoring of vital signs, helps detect abnormalities, and enables intervention. Patients can take proactive measures to prevent severe health issues at early stages as soon as an abnormality is present.

Insulin Pumps

Insulin pumps deliver insulin into the body constantly throughout the day via a catheter or cannula that’s inserted under the skin. Springs are employed in insulin pumps to regulate the correct quantity of insulin that’s being delivered into the patient’s body to guarantee accurate dosage delivery. They ensure precision and accuracy to avoid under or overdosing the patient.

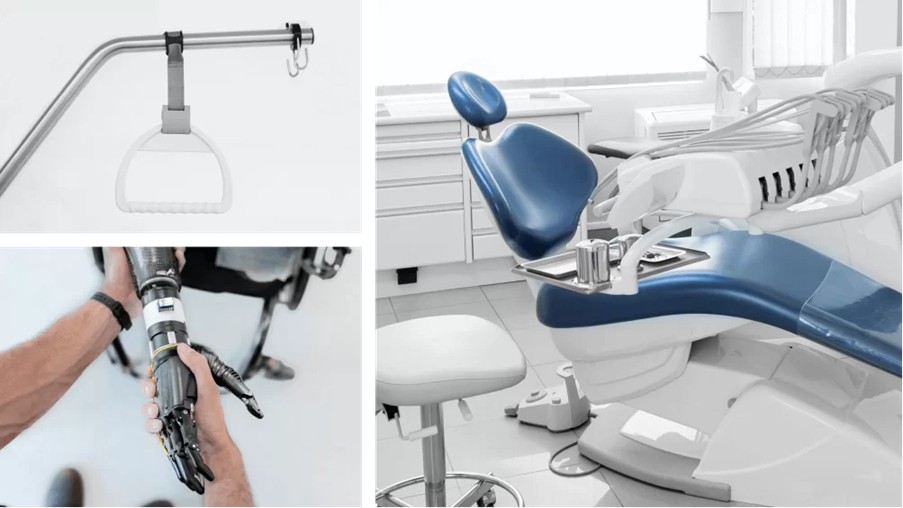

Prosthetic limbs

Prosthetic libs are assistive devices used to enhance mobility. They can help maintain your musculoskeletal health. The moving parts at the joints might include mechanical springs and gears or a microchip. Some prosthetic limbs may even include hydraulic or pneumatic cylinders to make motion smoother.

Springs in prosthetic limbs are used to store and release energy during movement to imitate the natural functions of muscles, providing smoother movement and stability.

Smart medical devices

Springs are an essential component used in a wide range of medical equipment and devices. Their use play an important role in the innovation and manufacturing of medical instruments.

Exoskeletons and Assistive Devices in Supporting Mobility

Exoskeletons are wearable devices that use springs to imitate human motions. Like the functions of human muscles, springs are powered by exoskeletons to carry out tasks like lifting heavy objects, running or standing for a long period of time.

To put it into perspective, picture a worker trying to lift heavy boxes. The springs expand to store energy as the worker bends to lift, and when the worker stands up, the stored energy turns into kinetic energy to assist the worker.

Regardless, the spring extension must suit the specific user; it is highly customisable as the required tension differs depending on the user’s physical characteristics and use of the exoskeleton. The spring improves the exoskeleton’s functionality, safety and user experience. A spring with the correct dimensions and tension should improve the performance and protection of the exoskeleton.

We have created small clips to fit within larger medical components to produce medicine aids. This works as an indicator flag, so that the patient knows if the medicine is being received.

How Springs Enhance Efficiency to Reduce Fatigue

These springs work by absorbing force when they are condensed or stretched and then releasing this force when the load is removed. They are used to deliver the required tension or contraction required for efficient energy transfer.

The exoskeleton helps reduce fatigue by assisting with movements and taking some of the physical load off the user’s muscles, leading to less muscle strain and exhaustion, particularly during physically challenging duties; this also means an improvement in physical endurance.

Examples of Assistive Devices That Relies on Springs and Pressings

In mobility aids, springs and pressings are commonly used to provide adjustable tension for shock absorption to ensure smooth movements. These are often seen in features like seating, adjustable heights, leg rests, folding mechanisms on wheelchairs, crutches, and more. When selecting springs for mobility aids, it’s essential to choose them carefully to ensure they serve their specific purpose effectively. They should be made from high-quality materials that are durable, prioritising safety. Luckily, at European Springs, we are the leading manufacturer in Europe, only providing clients with the best springs and pressings designed for reliability and sustainability.

Future of Wearable Technology

Wearable medical devices have transformed healthcare over the last decade. They have developed from simple gadgets to advanced technologies.

The future of wearable technology is expected to see more blending with everyday life, with devices decreasing in size to be more discreet and more personalised. Implementing smart textiles to wearables containing electronic elements to enhance detection and analysis is also an innovation that might alter the future of wearable technology.

As a custom spring manufacturer, we understand that it’s crucial to have the right component for a product, which includes wearable technologies. So, make sure to contact us if you require springs that need to be tailor-made for a specific product.