Metal stamping and metal pressing is the creation (forming) of a shape in metal. This is a fundamental process in modern manufacturing, transforming flat metal sheets into complex components with uses across various industries.

As a pressings and stampings manufacturer, we specialise in creating both bulk quantity orders and custom prototypes. Whether your application is unique and requires a specific solution, or you’re in need of a high volume production run, we can assist.

We produce products for companies all over the world, for applications ranging from defence and aerospace to medical devices and automotive.

The History of Stamping and Pressing

Going back as far as 1880, stamping and pressing technology was built on the foundations of blacksmithing. In the past, blacksmiths would use hammers, anvils, and forges to coldwork metal, but in the age of industry, this quickly became automated with the creation of steam-powered hammering machines.

Since then, we have been refining our manufacturing process to get to where we are now – high-quality products made quickly and efficiently. If you want to read more about the history of stamping and pressing, we recommend that you read our blog: A Brief History of Pressings and Stampings.

What is the difference between stamping and pressing?

The words ‘stamping’ and ‘pressing’ are used interchangeably but refer to the same process. In the manufacturing industry, there are slight differences when people refer to stamping or pressing:

- Metal Stamping typically refers to the entire process of shaping metal and can include punching and bending.

- Metal Pressing often is the application of pressure to form metal, focusing on the level of force used.

Where are metal pressings and stampings used?

Pressings and stampings are in many important products, including:

- Bicycle parts: Whether it’s e-bikes or traditional bikes, sheets of metal are bent, coiled, and pressed to create essential parts.

- Aeroplane and car parts: From large parts of the body to interior components and exhaust systems.

- Electronic components: Clips and brackets found in circuit boards or connector housings are often metal pressings.

These are some of the more popular use cases of metal pressings and stampings, but we’ve worked with many businesses who had a rare application. One such example is the Shimcup, where we were tasked with creating the world’s flattest folding cup. This innovative and travel-friendly example just goes to show the complexity of how metal pressings are used.

How is stamped metal made?

The process of metal stamping is straightforward, and the steps can depend on the desired result:

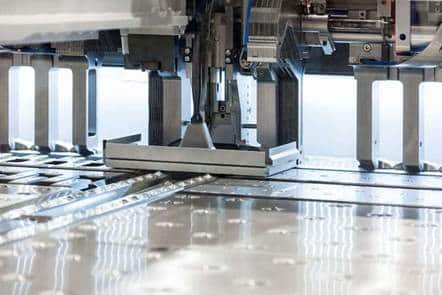

- A flat sheet of metal is inserted into a specialist machine often referred to as a stamping press, but also sometimes called a power press.

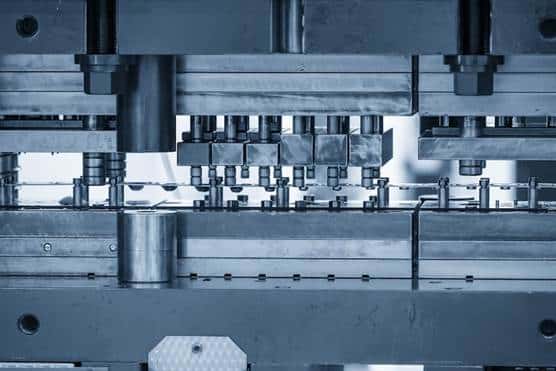

- This metal is then formed into the correct shape(s) through the use of a metal die. A die is an implement which is pushed into the sheet metal. This forces the sheet metal to take the shape of the die.

- After the metal is shaped, it may undergo further treatment including punching, blanking, embossing, bending, flanging and coining.

Punching – The desired metal shape is punched out of the surrounding material.

Blanking – The process by which a flat shape is cut out of the material, this process usually leads to further processing. Did you know that all drinks cans start off as circular blanks?

Embossing – A shallow depression is forced into the material.

Bending – The material is shaped in one direction. This can happen multiple times to produce a particular shape.

Flanging – Like bending, but along a curved edge.

Coining – Named after the item it was initially used to create; coining is the process by which a pattern is compressed into the flat sheet metal.

There are many other types of pressings too, including stretching, necking, and hemming.

What materials are pressings and stampings made from?

We work with a number of materials built to suit any industry’s requirements, including:

- Carbon and Stainless Steel: Popular and versatile, with different grades and shapes.

- Beryllium Copper: Strong, electrically conductive, and corrosion resistant.

- Copper Alloy: Thermal and electrically conductive, ductile, and durable.

- Nickel Alloy: High-temperature endurance, wear resistant and corrosion resistant.

- Aluminium: Lightweight yet strong, machinable, and sustainable.

- Brass: Easily formed and machined, aesthetically pleasing, and electrically conductive.

- Melinex: Polyester film, flexible, and thermally stable.

If you have a particular project in mind, get in touch with us so we can discuss which materials might best suit your designs.

There is even technology that can run your pressing design through simulation software on a computer to ensure that it will withstand the strain of the application it is going to be used in, so ensure that you make the most of our design support when placing an order with us.

If you have any further questions about the processes of our metalworking, contact us directly and we’ll work with you to make your next product design a reality. We’ll provide you with prototypes to ensure that your vision is executed exactly how you imagined.