At European Springs we pride ourselves on our dedication to quality and innovation, keeping our fingers on the proverbial pulse of engineering and its subsequent advances.

Manufacturing everything from custom springs to wire forms, we are always intrigued when we hear of innovation in a similar field.

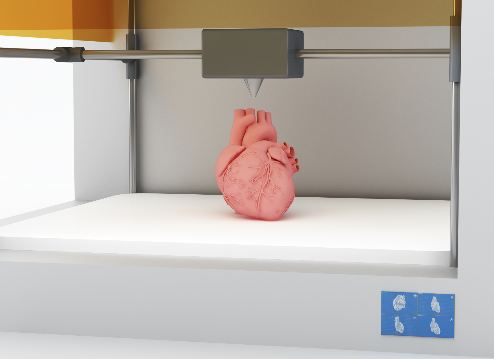

The great thing about engineering is the industry’s ability to continually improve standards of living, be it through subtle changes or grand improvements. With the increase in the availability of 3D printers, there are continuing stories of innovation hitting the news as more and more people realise their pseudo-casting potential.

Parts for Organs

Through a process called 3D bioprinting, there is an increasing ability to be able to construct custom repairs for damaged parts of organs. For example, one could create bespoke sections for damaged windpipes by combining the 3D printing technology and tissue engineering to connect, or fuse, the sections of a windpipe.