Is the Manufacturing Industry Ready for Industry 4.0?

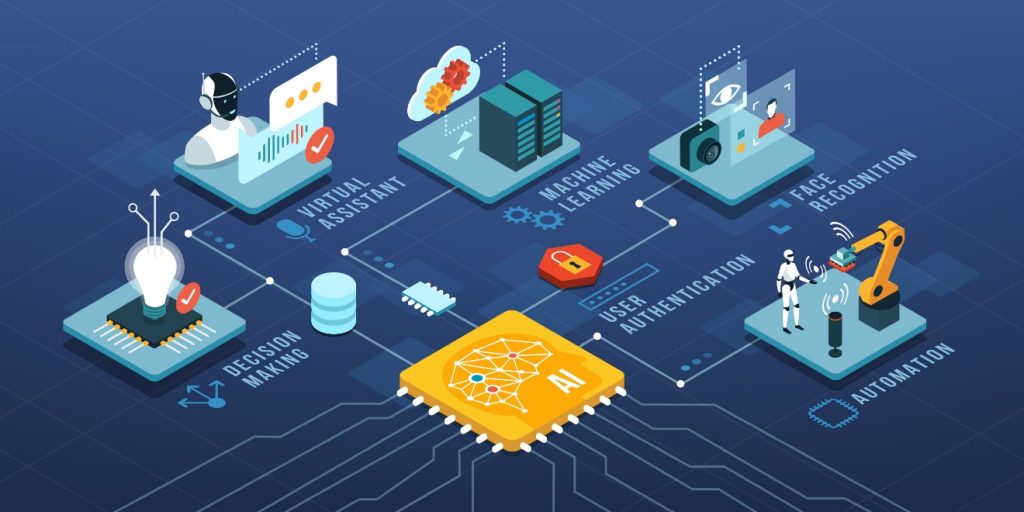

Driven by the need to access insights in real-time, Industry 4.0 is the name that has been given to the current phase of the industrial revolution. It’s heavily focused on integrating smart technology, automation and machine learning, with current manufacturing practices.

We will be looking at whether the manufacturing industry is ready for these big changes. Are we ready to embrace Industry 4.0, and more importantly, what role will it play in building a new strategy after Covid-19?

Is the Manufacturing Industry Ready for I4.0?

Industry 4.0, sometimes abbreviated to I4.0, will bring significant change to the way our nation’s manufacturing companies are run. Increased automation will mean that fewer production line jobs will be required, profits will be made from increased output and efficiency, and that this profit should initially be invested on training bottom line workers to successfully oversee and maintain mechanical operations.

The question of whether Industry 4.0 is happening is a moot point: the revolution is already in progress. The real question, then, is whether our nation’s businesses are ready to take advantage of this new technology, and what will become of those companies that fail to invest in automation soon enough.

Overall, statistics report that our nation’s manufacturers at large are ready and willing to embrace big changes. In fact, the Annual Manufacturing Report from 2019 found that 81% of manufacturing companies wanted to invest in new technology to boost productivity. Many will note, however, that there is a marked difference between wanting to invest and being ready to.

Are You Ready for Industry 4.0?

If you are one of the companies that are keen to invest in Industry 4.0, then there are a few things that you can do now to make sure that you are ready to implement this new technology as soon as you are able.

Here are some questions that you should be asking yourself:

Can I Cover the Potential Costs of I4.0?

Installing the technology will have its own costs, so you will need to prepare a substantial amount of savings for your business before you can consider cashing in on the benefits of I4.0 technology. Finding this money starts with speaking to the creators of I4.0 technology and getting rough estimates on potential costs for your business. From there, it is a matter of making good savings until the equipment you need becomes available.

How Will My Staff Need to Change?

Understandably, your bottom line might feel a little intimidated by the eventuality of Industry 4.0 technology, and as a good employer, this is an anxiety that you should try to address. Inevitably, the shape of your current board of staff is sure to change as efficiency improves and more technological maintenance is required. If you’re sure that you are going to be implementing I4.0 technology in your business, then you should be considering costing up future training for your employees now.

Can and Should I Wait to Implement this Technology?

There are two different schools of thought regarding whether or not you should dive into new technology the moment it hits the market. On the one hand, this technology could help you to move beyond your current competitors as you improve your efficiency and gain more time to focus on staff retention, customer loyalty and marketing.

On the other, if you are a little sceptical about how advanced logistics, immediate data reports and automatic inventory calculations will help your business – waiting a while to learn the truth of how this technology has benefitted other businesses may permit you to cost up the advantages of investing in this technology more effectively. Until the technology becomes more widespread, it is hard to judge the precise effects that this investment will have for you.

What Are the Green Benefits?

We are tension spring manufacturers who are interested in green responsibility, and we believe that I4.0 has the potential to reduce waste in manufacturing. With improved logistics, manufacturing will be able to better understand where waste is occurring and discover ways to reduce this. Doing so should have economic benefits for the company, too, so it’s happy all round.

If you are in need of spring manufacturers for your next project, we’re experts in the industry. We combine smart technology with decades of experience. For custom springs or opinions on the latest industry trends, you can rely on us.