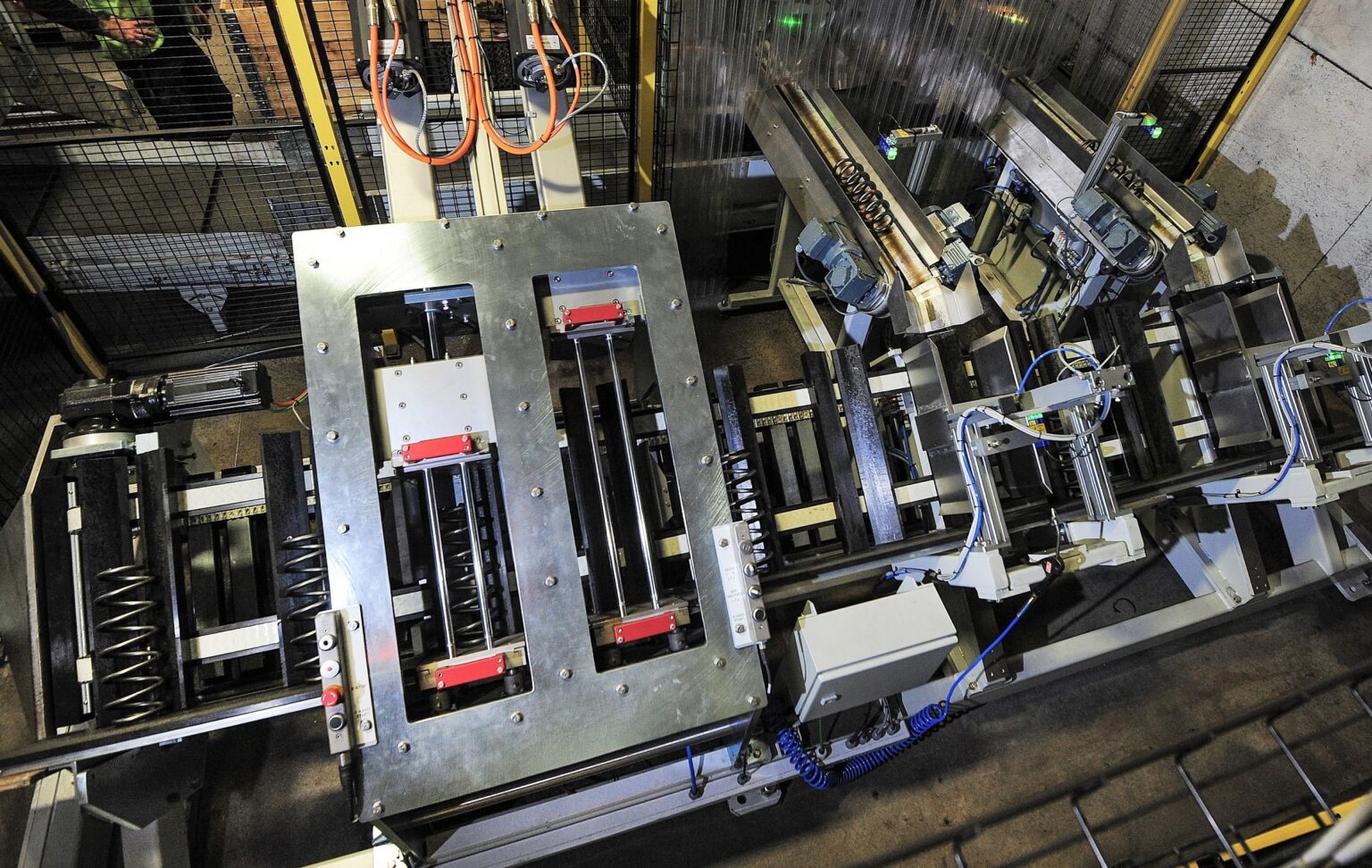

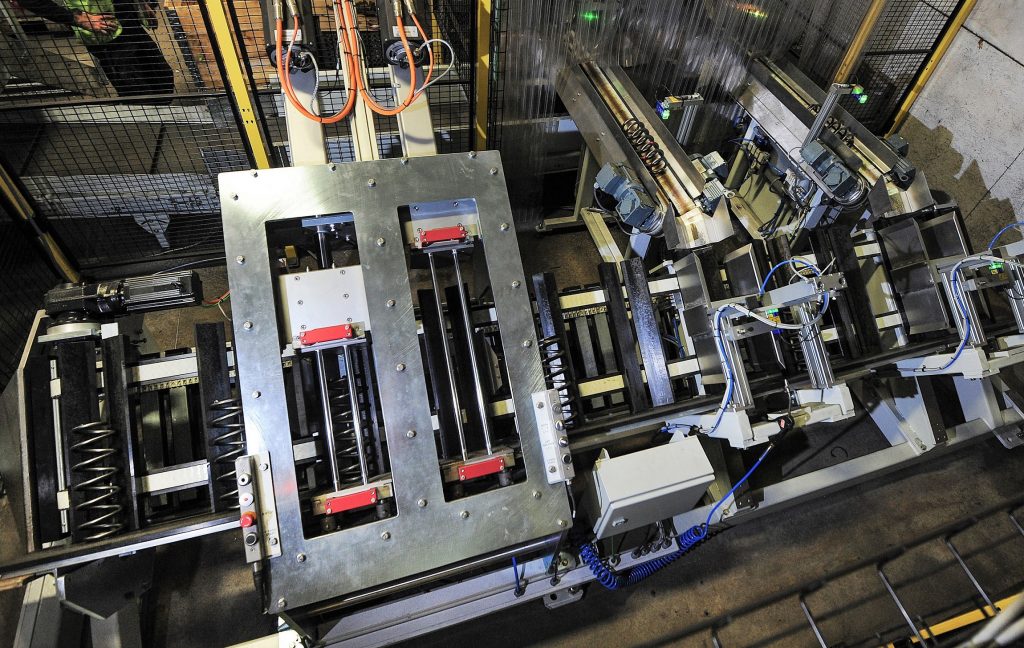

Taking the stress out of pre-stressing, European Springs & Pressings (ESP) have invested in a unique invention, with the design and manufacture of an automated pre-stressing machine.

Working alongside Design & Automation Solutions and Bosch Rexroth, ESP have seen their conceptual plans taken from the drawing board, designed and delivered, with a new automated pre-stresser (which improves the life and load bearing capacity of a spring), reducing waste across multiple processes.

Michael Gibbs, Managing Director of ESP in Cornwall says: “In the last decade, since we were acquired by the Lesjofors Group, we have seen turnover increase by over 700%, which has recently led to the acquisition of a second factory in Cornwall and a 40% increase in recruitment in the last year. Lean manufacturing has been key to our success and enhanced automation not only increases our efficiencies in operations and production but also on the budget sheet, as we estimate a pay-back period within just 5 years.”

Mick Stallwood, Director of Design & Automation Solutions adds: “Manufacturers are under constant pressure. Multiple factors demand more out of them and manufacturers demand more out of their facilities and infrastructure. This is where we step in. Our specialisms, in advancing technologies and automation, have been utilised world-wide and to design a world first for one of the world’s leading spring manufacturers, is something we’re very proud of. Reports suggest the UK automotive sector is down but ESP are showing otherwise and the ripple effect of successful projects such as this shouldn’t be under-estimated, as we are now expanding with new premises due to an increase in demand.”

Gibbs concludes: “The automotive sector of our business has grown exponentially, hence the recent purchase of an additional factory. With significant investment in new spring coiling machines, a new powder coating line and other ongoing investment intentions, further adding to our Industry 4.0 capable manufacturing technology, I have great confidence in our manufacturing future.”