Imagine a World Without Pressings and Stampings

The world is full of objects and components that have been stamped and pressed, some of them are things you would never even think of, but without this fantastic process the world might be a very different place.

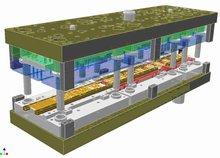

The process of creating bespoke pressings and stampings can be used to create a number of different components out of a variety of materials, meaning that it can be used across numerous industries to craft the world we know today. It’s important that these components are made to a high quality, to this end our new pressing and stamping machine is in full swing to provide you with the bespoke stamping for your needs.

What is the Stampings and Pressings Process?

Stamping, a process also known as pressing, is a tool used to transform sheet metal into a desired shape, including stainless steel, copper, brass, or aluminium. This process can occur during a single stage or can be carried out through a series of stages. Stamping has a fascinating history, going as far back as the 1880s.

Coins Wouldn’t Exist

To produce coinage, a form of precision stamping is needed, a piece is subjected to high stress to induce plastic flow on the surface of the material. A benefit of this process is that in some metals the flow of plastic can reduce surface grain size, harden the surface of the coin and the material beneath the surface maintains its ductility. It is a cold working process that uses a great amount of force to deform a piece so that it will conform to a die.

Coining as a process is used to manufacture parts for other industries, even though it was named after its ability to make coins when it first came to be. However, it is also used to produce medals, badges, buttons, precision parts and precision-energy springs.

The Health Industry Would Be Affected

Of course, although it is said that money makes the world go around, the health industry also requires precision pressing and stamping. Medical supplies obviously have to be precise, well-made and reliable as they are employed in the service of saving lives on a daily basis.

As a result, more and more high-performance materials are being used such as carbide progressive dies for blanking, bending and the deep drawing of the titanium that is so commonly used to create medical equipment.

These pieces combine functionality and design in order to deliver high-precision that such an industry requires. Mistakes are not acceptable on such a level and so the stamping and pressing machine has to be perfectly calibrated to create the almost perfect products required.

Pressing and stamping is an integral process for many areas of the modern world and it has helped bring us into this era of technological advancement that we currently live in.

Our stampings and pressings equipment at European Springs is amongst some of the most technologically-advanced in the world. Being unique for each product, we can produce your desired product at low cost and with a high level of flexibility.

If you would like to learn more about what we do and how pressing and stamping can advance your production, then get in touch with our fantastic team at any time, we are happy to answer any questions that you might have.

European Springs