Springs for Smooth Travel in the Rail Industry

As an experienced spring manufacturer, we see many uses for our springs throughout the transport sector, particularly within the rail industry.

Custom springs are used frequently throughout the rail network for suspension systems, pistons and as supports. In this blog, we’ll explore how springs are a vital component in trains and their functionality.

Springs and Bogie Systems in Trains

The hydraulics system within trains helps them to run smoothly along the tracks. The weight of a train is supported by a hydraulic system which creates a sliding movement with little friction and abrasion

Engineering within the rail industry has come a long way. From early steam trains to fully spring-reliant electric systems.

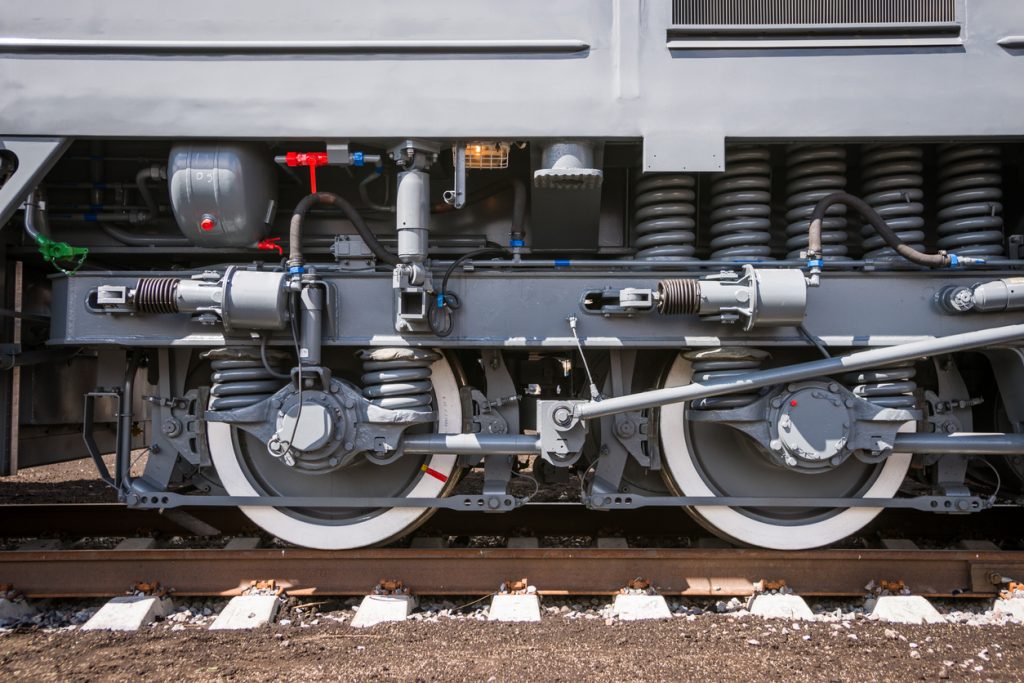

In the UK, most trains use bogies to guide the carriages along the tracks. The bogie of a train is the undercarriage and usually has four to six wheels pivoted beneath the end of the vehicle. It is divided into the frame, the bolster, the pivot pin, the wheel assembly, roller bearing, the brake beams, brake block, brake levers and brake cylinders, all of which are vital to the structure of the bogie.

These systems have been developed and improved over years of design and testing. Bogie suspension systems were implemented because the space between the body of the train and the wheel needed a ‘cushion’ to reduce vibrations for passengers. By mounting a leaf steel spring on the axles, engineers have developed a bogie system with a more sophisticated suspension.

Primary Suspension System and Dashpot Arrangement

The primary suspension is made up of a standard spring-damper system that supports the carriage’s structural suspension and entire train. These damper systems are present in every bogie existing between the axle box and the bogie.

The primary suspension component in a bogie is through a dashpot arrangement, which comprises of a cylinder piston. The lower spring seat acts as a cylinder, and the axle box guide serves as a piston.

The bogie bolster, or support, is the central section of the area and will carry the majority of the coach weight. The bogie pivots around using the pin, which is centred and uses parts of the secondary suspension system, typically coil springs and a spring plank.

Dashpots can also be found within door closers to prevent them from slamming shut, as well as in shock absorbers in electrical switch gears, and so much more.

Secondary Suspension System

The secondary suspension connects the carriage’s body with the bogie and ensures the comfort of passengers — isolating the vehicle from vibrations transmitted from the track.

Air springs also help to reduce lower frequency range accelerations in the body of the train. The role of secondary suspension is to function as a pneumatic suspension. This type of suspension is also used in freight trains to keep cargo as secure as possible.

Bolster Support in Suspension Systems

The arrangement of the secondary suspension system is through the bolster springs. The bogie bolster is not structurally attached to the bogie frame. It is, however, connected through the anchor link, which is a tubular structure with cylindrical ends.

The anchor link is fixed to the bolster and the bogie frame with the assistance of brackets. Both ends of the anchor link form a hinge that allows movement of the bolster when the train is in transit.

If your business works within the rail industry and you’re looking for a custom spring manufacturer capable of meeting your business requirements, please contact us to start a conversation or look at our spring brochure for a more details of the products we stock.