Springs are vital components in highly dynamic machinery, ensuring durability, stability, and smooth operation. These machines are widely used across industries such as construction, automotive, and manufacturing, making springs essential for various applications.

In this blog, we’ll explore the vital role springs and pressings play in dynamic machinery, key factors to consider when designing and manufacturing them, and the industries that rely on these precision-engineered components. From automotive and manufacturing to construction, we’ll examine how springs contribute to performance and longevity.

At European Springs and Pressings, we provide expert design, prototyping, and specialised surface treatments to ensure your springs and stampings perform optimally, even in the most demanding environments.

What is Highly Dynamic Machinery?

This term refers to machines that experience fast movements, a high volume or frequency of cycles, and intense force or pressure as part of their operation. It is important that these machines can endure heavy loads and high speeds without failure, and springs form a central component of their existence. Here are some examples of highly dynamic machinery:

- Vehicles: Suspension systems in various vehicles such as cars, lorries, and airplanes utilise springs for maintaining smooth movement.

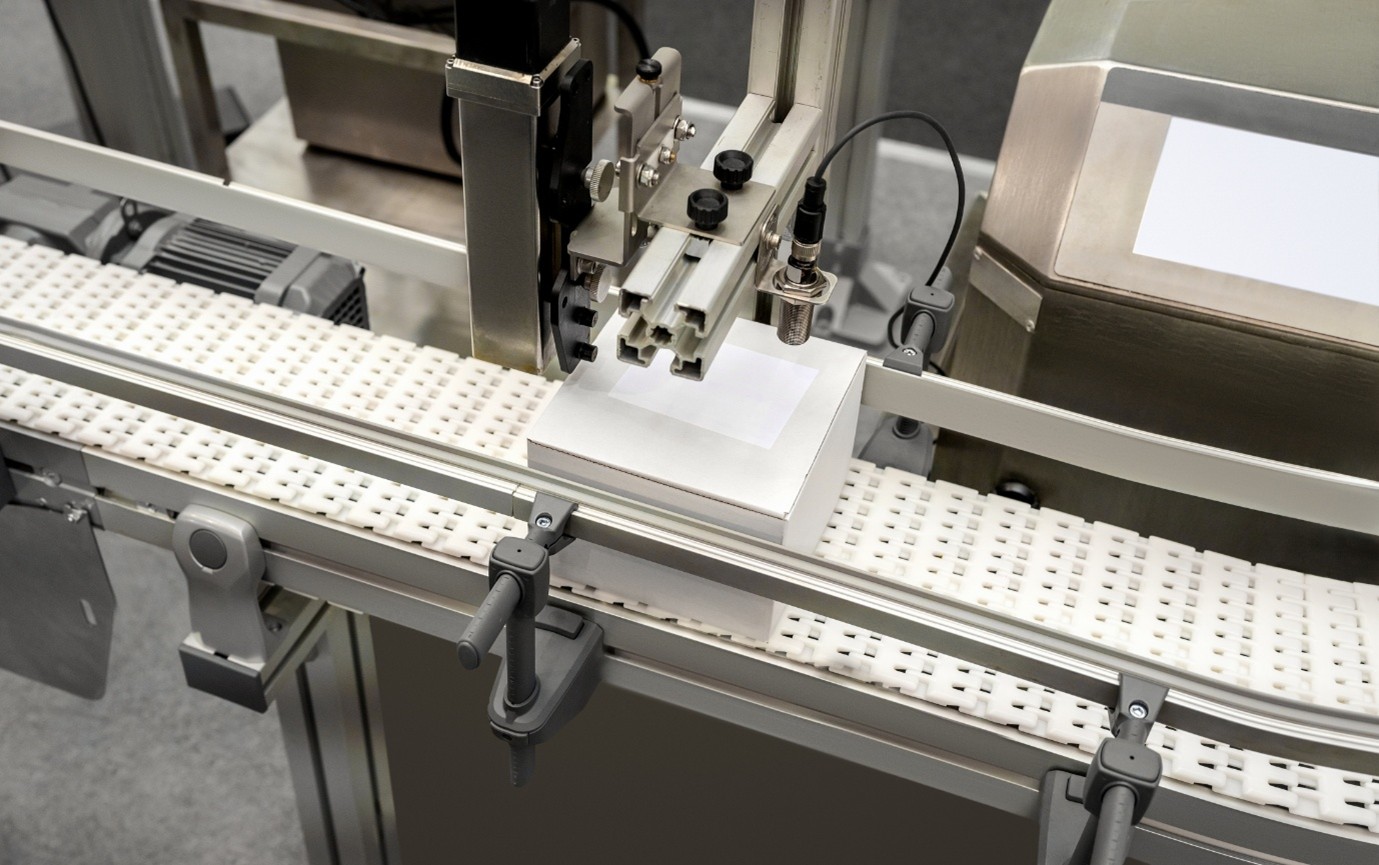

- Automated Packing and Sorting Machines: Machines used in logistics and distribution centres that rapidly sort and package goods, often with high-speed conveyor belts.

- Construction Machinery: Equipment like cranes experience heavy loads that need to be managed effectively and safely.

- Aerospace Components: Things like landing gear and actuators in aircrafts must be able to handle quick movements and sudden changes in force and pressure during take-off, flight and landing.

These are just a few examples of highly dynamic machinery that incorporate springs in their operation, but equipment of this sort can be found in a variety of different sectors and applications.

Static Load vs Dynamic Load

When designing springs for machinery, it’s crucial to understand the difference between a static load and dynamic load.

Static Loads are loads which feature an unchanging load or force. An example would be a weight resting on a support. In this case, the spring’s function is to support the load without changing position, keeping it securely locked into place.

Dynamic Loads involve forces that can vary over time. An example of a dynamic load would be a car’s suspension system, where the load changes constantly as the vehicle moves over uneven surfaces. Forces can change based on motion, shock, vibration or acceleration, meaning that the springs must be adapted to these adjusting factors.

Factors to Consider when Designing Springs for Machinery

If you have a dynamic application, then it’s important to consider the different elements that could impact the design and functionality of the spring. Here are some examples:

- Load Requirements: Both the static and dynamic loads must be considered when designing a spring for this kind of application. Understanding the magnitude and frequency of loads is a vital step in the spring manufacturing process.

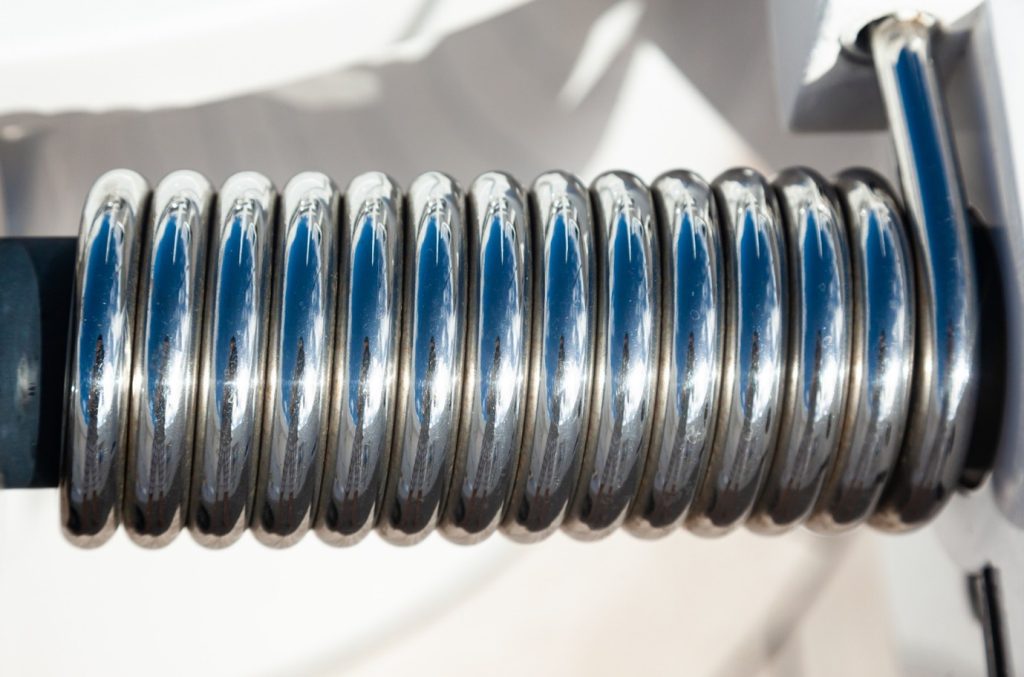

- Material Selection: Since these applications are subject to quick motion and heavy loads, it’s important to select a durable material that will not deteriorate quickly. For instance, stainless steel and carbon steel are favoured in these environments for their strength.

- Spring Type: This factor is subject to the type of application, as each of the springs we offer provide different advantages. For example, compression springs are used within suspension systems, as they provide resistance when they’re compressed. Alternatively, constant torque springs are utilised in areas where continuous tension is needed.

- Surface Treatments: We offer a selection of surface treatments that can be added to your custom spring to make it more adapted to a highly dynamic application. If corrosion resistance is something needed within your spring, then we can cater to this requirement through surface treatment.

Highly Dynamic Machinery in Different Industries

Machinery of this nature is found in many different sectors. For example, in the automotive industry, springs are crucial for vehicle suspension systems and safety mechanisms. They must be able to perform in conditions of acceleration and deceleration, as well as instances of unpredictable movements. Within this environment, it is imperative that vehicle components can function reliably under dynamic driving environments.

Similarly, springs are often found in manufacturing and automation. Equipment like packing and sorting machines need to run effectively at high speeds, relying on springs during the process. They are found in actuators, sorting mechanisms, and conveyor belts, absorbing shock and enabling the smooth movement of items.

The construction industry involves a great deal of machinery, often involving heavy and dynamic loads. For instance, excavators use springs within hydraulic systems to control movements of the boom, arm, and bucket. Equally, the suspension systems in loaders and cranes use springs to provide smooth rides and assist with shock absorption.

At European Springs and Pressings, we understand the importance of reliable spring and pressing products within these applications. Our team of experts offers end-to-end support in the design, prototyping, and testing of springs, ensuring that every solution is tailored to the specific demands of machines. To learn more about our processes, or to enquire about springs for your highly dynamic application, please feel free to contact us.