Did You Know? Compression Springs Interesting Facts

You know that springs are our speciality. But how much do you know about springs? While many people can tell what a spring is, identifying it as a helical-shaped component that will compress when exposed to external forces and return to its original form immediately afterwards, they are completely oblivious to the numerous designs and sub-types they come in or how they are made.

As experienced spring manufacturers, we know how vital springs are in various industries across countless systems and specific applications and want to share a little more about them. In today’s blog, we will explore details and interesting facts about one of the most popular spring types we manufacture: compression springs.

Spotlight on: Four Different Compression Styles

When you think about springs, you are likely thinking of compression springs. This type is one of the most frequent and recognisable across a multitude of applications; its main function is to resist highly compressive forces and return to its original shape when the force or load is removed, releasing energy. But we know this, of course. What is interesting, and probably lesser known, about compression springs apart is their availability in a wide range of compression styles, each designed to meet specific requirements. Let’s have a look at each style.

Straight Springs

Straight springs are the most prevalent type of compression spring in various applications. With both the inner and outer diameters remaining constant throughout the length of the spring, their simple design makes them highly versatile and easy to manufacture. We can find straight springs in everyday items such as ballpoint pens, mechanical pencils, and several mechanical devices where reliable performance is essential.

Mini Springs

These spring types are essentially scaled-down versions of straight springs: the two look identical; they are just smaller. Their fantastic compactness and precision make them the preferred choice in the aerospace and marine industries, especially when it comes to delicate instruments and controls, where space is limited but precision is non-negotiable.

Hourglass Springs

As the name suggests, these springs have a distinctive shape. Their diameter tapers at the centre, forming an hourglass shape. This unique design allows for more uniform stress distribution along the length of the spring, providing stability and preventing buckling under compressive loads. Because of this, hourglass springs are often found in complex machinery and automotive components.

Die Springs

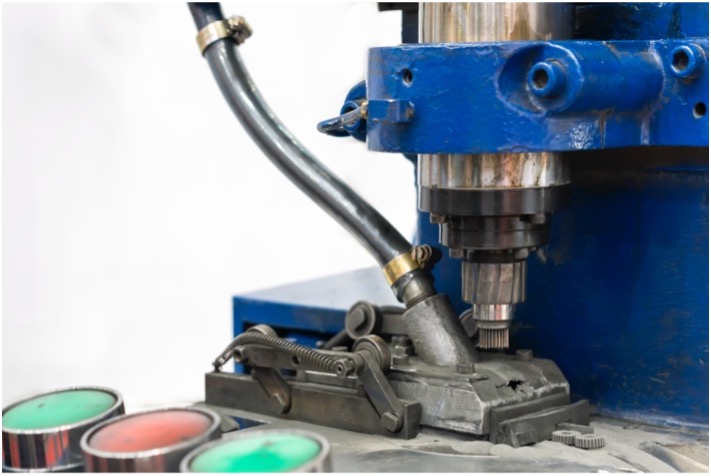

Die Springs

Die springs, also known as high-force compression springs, are robust helical compression springs made from rectangular wire and are designed to carry significantly heavier loads than other compression spring types. They can withstand high stress and work fine in difficult and harsh environments, such as industrial machinery, metal pressings, and die-casting applications where heavy-duty performance is essential.

The Five Different Spring Ends

Beyond different compression types, we also have different compression spring ends; each spring end affects the spring’s pitch, height, and overall characteristics, influencing its overall performance and suitability for particular applications. Understanding this aspect will help you choose the right spring, so let’s take a closer look right away.

Open-Ground Springs

Open-ground springs are characterised by their last coil being flat, while pitch is not reduced throughout the rest of the spring. This design provides excellent stability so that the spring stands evenly under compressive forces. For this reason, they are often used in automotive suspensions and industrial machinery.

Open-End Springs

Open-end springs are successfully employed in applications where a steady rate of compression and expansion is critical. They maintain a consistent and reliable coil pitch throughout their length, making them ideal for a wide range of applications, from simple household items like pen mechanisms to complex medical devices.

Closed-End Springs

Closed-end springs feature a reduced pitch at the end of the coil. This reduction in pitch at the ends provides greater stability and support and helps to distribute the load more evenly, reducing the risk of deformation. They are often found in precision instruments and sensitive mechanical assemblies.

Closed-Ground Springs

These springs combine closed-end and open-ground springs. They have a reduced pitch in the last coil and a flat end for enhanced stability and support. The flat end ensures that the spring sits evenly, while the reduced pitch at the ends distributes the load more effectively. They are a popular choice in automotive engines and high-precision industrial equipment.

Specialised Spring Ends

In addition to the common types of spring ends, several specialised designs created to suit specific requirements deserve special mention. For example, double-closed ends, where both ends are tightly coiled, offer even greater stability and load distribution.

Why Spring Safety and Durability Go Hand in Hand

Many people don’t think about spring safety, yet it is absolutely essential for ensuring these components’ longevity and performance. Proper care and regular inspection of compression springs, especially during their manufacturing process, can prevent damage and extend their lifespan. Safety protocols typically involve routine checks for wear and tear and complying with the highest safety standards.

To improve compression springs’ safety, it is important to enhance their durability. spring manufacturers like us employ several valid techniques, for example:

- Shot peening is a process that enhances the fatigue strength of the springs by inducing compressive residual stresses.

- Plating the springs with corrosion-resistant materials protects them from harsh environmental factors.

- Proper installation contributes to the longevity of compression springs.

Whether you need standard or custom compression springs or are looking for information on how our products can benefit your business, we’re here to help. At European Springs, we pride ourselves on our extensive expertise and the quality of our springs; download our spring catalogue and reach out to our team to learn more. We are dedicated to providing top-notch service and innovative spring solutions to meet your specific needs and help you achieve your goals.

Die Springs

Die Springs