Mechanical springs are present in every area of our lives, and it is easy to take these practical components for granted. A humble spring may seem simple, but manufacturing high-quality springs involves implementing a surprising number of complicated processes.

What Is Spring Winding?

The first step, spring winding, is the generalised term used to cover the many different ways springs are physically manufactured. This name is related to the winding nature of most spring designs but with slight changes for each type.

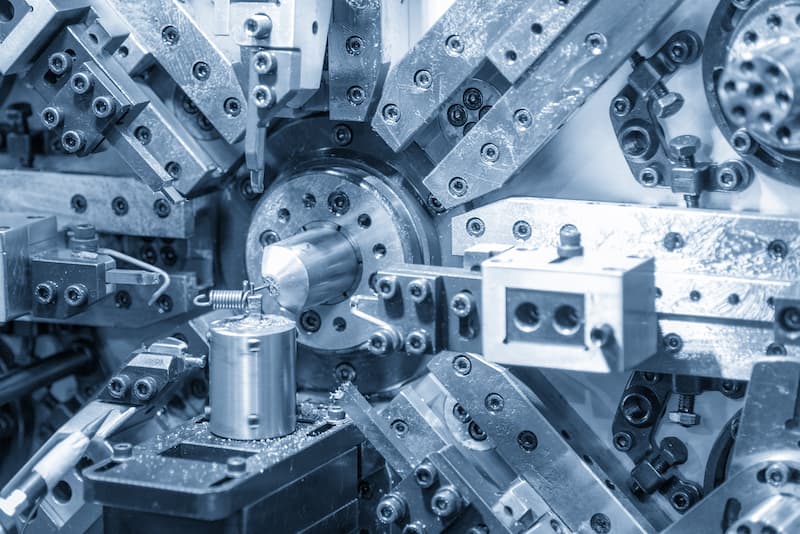

Spring wire is fed into one of our advanced CNC (computer numerical control) machines, which will be straightened into a default, flat shape before being manipulated into the desired result.

Coiling Machines

Spring coilers will feed the wire into rollers that draw it through guides that culminate in a coiling point. The wire is coiled backward at this point to form the intended spring shape. This is used to create many custom spring designs, such as tension, torsion and compression springs.

Forming Machines

We use forming machines to create tension, torsion springs and varied wire forms. A spring-forming CNC machine will have six to eight tooling slides on the face which help it perform several bends and hoops in addition to the standard spring coil. As a result, this machine has more adaptability than a coiling machine.

Bending Machines

Computers control our CNC bending machines as they use a variety of uniquely placed rollers. These rollers will form the inserted flat wire into bespoke wire form designs. Then, rollers moving tool heads, and guides push and pull the metal into the final design. This machine is usually chosen for high-quality wire forms but can be used for bespoke spring designs.

Heat Treating Springs

The second step, heat treatment, is a beneficial process that helps improve the quality of the material of the spring. The heated processes will modify the crystalline structure of the metal alloys through repeated heating and cooling. This will be conducted at different intensities and durations, with the effect on the material being:

- Increase durability

- Higher temperature resistance

- Increased ductility

Spring manufacturers provide this service as part of the metal fabrication process because it has dramatically improved physical properties without altering the dimensions. Common heat treatments are hardening, annealing, quenching and tempering.

Hardening

Metal hardening is where the alloys are heated above the critical temperature for the material and then cooled again rapidly. There are various ways of quickly cooling the materials, including the quenching process. Few metals are only hardened; most will have additional treatments such as tempering or stress relieving to improve their workability and toughness.

Quenching

This cooling process has a significant effect on metals. Quenching can be done minimally with air cooling or dramatically with water or oil. The rapid cooling of quenching essentially freezes the microstructure of the metal and creates stress. This unintended side-effect can be fixed with tempering.

Tempering

The cooling process puts metal under strain, but that can be relieved with tempering. Tempering further develops the material’s properties and balances them out after the hardening and quenching process. The specifics will vary depending on the desired result and the material.

Generally, tempering involves reheating the cooled metal at a relatively low temperature. The material’s microstructure creates chemical precipitation and spheroidzation of the internal elements. Spheroidzation is particularly relevant to compression springs as it assists with rolling the coils.

Annealing

This process aims to increase ductility, specifically, making the material more malleable without fracturing. This reduced hardness is because the annealing process reduces the dislocations inside the metal’s crystalline structure.

Dislocations are defects inherent within metals. These irregularities strongly influence the properties of the metal, with an excess number increasing the metal’s corrosion susceptibility. Therefore, annealing is usually performed on materials that have been cold-worked or hardening to prevent the metal from becoming brittle.

Coating and Finishing

The final phase of spring manufacturing involves applying coating, plating or other finishing processes. If heat treatment is about the internal quality of the metal, then this stage addresses the external surface.

Spring manufacturers ensure their springs have the most extended longevity by applying effective coatings that prevent corrosion and improve visual aesthetics.

Shot Peening

Shot peening is where the finished springs are attacked with spherical shots. This effect applies compression stress, which can be seen as compression dimples on the surface. In addition, shot peening strengthens the material against fatigue, corrosion and cracking.

Plating

A thin layer of metal is applied to the surface of the spring during an electroplating process – a mixture of chemicals and electrical currents attach the plating to the metal. This process improves corrosion resistance as a fresh layer protects the spring below. Plating is also used to improve a spring’s aesthetics or electrical conductivity.

European Springs has a long history of manufacturing the highest quality springs for companies globally. Leaving handmade manufacturing behind, we use advanced CNC machines to produce large batches of bespoke springs, usually using the many varied steps outlined above.