UK manufacturing is still feeling the impact of the last two years’ events. Production and economic disruptions created many challenges that the industry is still struggling to overcome. These obstacles have been exacerbated by more recent events, such as the Russian war in Ukraine and the erratic China lockdowns.

An unfortunate result of these problems is the rising cost increase that UK manufacturing has to manage. Supply chains are still recovering, and energy bills are rising, but the demand for British manufactured products is also growing. This increase in demand is outgrowing the supply to fulfil it, causing an increase in costs. So how do manufacturers address these costs and maintain their competitiveness within the industry?

National Insurance Increase

From April 2022, the UK government increased the National Insurance contributions (NIC) by 1.25% for the tax year. This means manufacturers would be required to contribute 15.05% for each workforce member as opposed to the previous 13.8%. With the industry already struggling to fill positions, there are concerns that this increase will make it difficult for employers to recruit new engineers. If growth is limited due to this, it could increase the existing skills gap and create significant problems for the productivity of many manufacturing companies.

The response to this increase varies, but 38% of businesses have stated that they plan to pass the additionally incurred NIC onto the customers, while others choose not to. Some companies cannot absorb the costs; in this case, letting inflation trickle down to the broader economy is a sensible solution; this can enable managers to protect their employees’ jobs and allow time for the situation to improve.

Increasing Energy Costs

There has been a sharp rise in energy costs during 2022, impacting everyone, domestic, commercial and industrial. However, the high energy nature of manufacturing means that these increases affect them more accurately than in other areas of the UK.

These sharp increases have forced manufacturers to assess every business area to increase energy efficiency and mitigate costs. This can include analysing the energy usage of processes, the requirements of various equipment, and even temporarily halting the most energy-intensive procedures.

Government Support for Industry

The manufacturing industry plays a considerable role in the UK’s economic output. Manufacturers employ roughly 2.6 million people across the country and are responsible for 44% of all UK exports. Despite the many issues the industry has faced, manufacturing remains a vital organ within the larger body of the county. Fortunately, the government may be taking steps to support this vital industry.

The UK government announced earlier this year that it would be providing support for high energy usage businesses that are struggling with the rising energy costs. The plan is to extend the energy Intensive Industries Compensation scheme and, thanks to its increased budget, be broadened to apply to more businesses, including steel manufacturing.

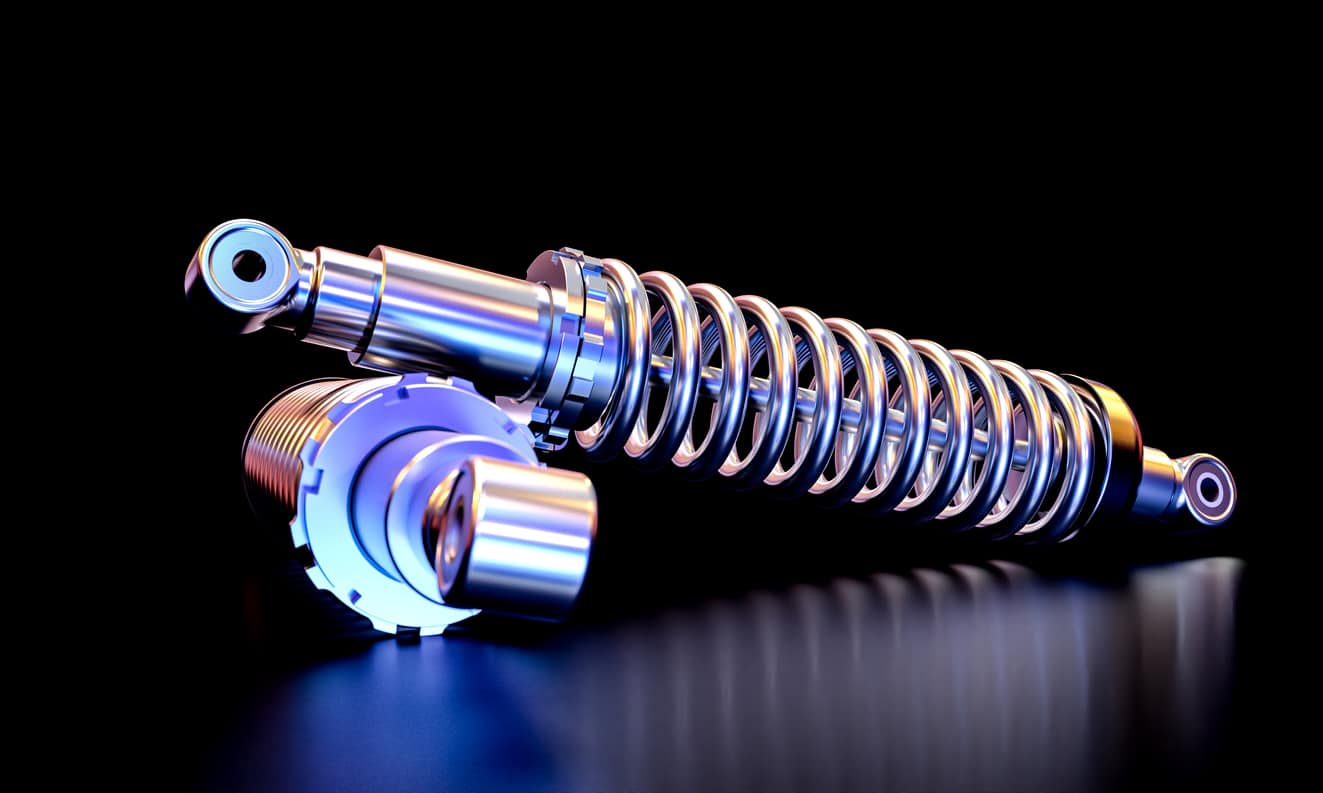

Industry Minister Lee Rowley said he wished to keep UK manufacturing at the forefront of the industry globally by providing this assistance. With the current changes to the scheme already having a positive impact on some areas of the sector, potentially, this support could be extended to include various other manufacturers, such as spring suppliers.

Choosing Local Power Generation

The rising costs of energy will inevitably have an impact on any manufacturer’s ability to remain competitive. These issues have not just been limited to financial expenses either. In a recent survey conducted by Aggreko, 65% of the 251 manufacturers stated that they had experienced an increasing number of power cuts over the last 18 months. The combination of the erratic market and unexpected power cuts harming operations has encouraged the manufacturing industry to explore on-site power and distributed energy solutions.

Distributed energy systems (DES) is a broad term that covers a diverse array of energy generations, control and storage options. This can be applied to on-site power generators and renewable solar and wind power sources. With the advances in renewable technologies, its become increasingly affordable for compression spring manufacturers to decrease their energy costs through solar panels’ on-site power generation. Additionally, with the load management installed, on-site managers can remain unaffected by widespread power cuts from more centralised sources such as national power stations.

Before national power grids were established, each business needed to develop its internal power generation. On-site power enables managers to specifically regulate the power they need as well as provide the desired energy security for their operations. Returning to this may be a solution for manufacturers to cut costs and improve their environmental efficiency.

Manufacturing’s Future

The importance of manufacturing for the UK economy and its high international standing ensures a bright future, but how to reach that destination is still unclear. These rising costs will continue to stress existing processes and test any innovations. Still, we at European Springs firmly believe that the industry’s resilience will be able to overcome any of these challenges.

European Springs plans to rise to these challenges presented and use these obstacles as opportunities to learn and explore. We are committed to constantly exploring new ideas and improving our methods to provide our clients with consistently excellent results with our bespoke pressings and springs.

Read more about why European Springs is a leading industry manufacturer here.