Here at European Springs, we are proud to share our commitment to sustainable solutions and are dedicated to reducing our environmental impact while maintaining high-quality products and services for our customers.

As a leading manufacturer of springs and pressings, we understand the importance of sustainability and reaching net zero goals in our industry and have taken steps to ensure that our operations are as environmentally friendly as possible. So, we will share our Sustainability Statement and discuss how we plan to reduce waste and energy consumption, how we use eco-friendly materials, and the ways in which we support the wider industry. Join us as we explore our sustainable solutions and strive to make a positive impact on the world around us.

Why Does Sustainable Spring Manufacturing Matter?

Sustainable spring manufacturing matters for a variety of reasons. Primarily, our planet is facing numerous environmental challenges, including climate change, pollution, and biodiversity loss. As spring manufacturers, we can reduce our environmental impact and help protect our planet for future generations by adopting sustainable practices.

As well as helping the planet heal, our sustainability initiatives (such as reducing waste and energy consumption) are helping us and our customers save on costs. Our sustainable manufacturing practices allow us to improve product quality and longevity, reducing the need for replacements. We focus on high-quality, sustainable products, meaning there’s less waste, fewer new materials produced, and more money saved in production costs.

How Do Our Efforts Impact the Wider Industry?

We’re firm believers that the small things make a big difference, which is why we’re always happy to try out new initiatives, no matter how minor they may seem at first. The efforts made by one manufacturing company, such as ourselves, to improve sustainability can positively affect the wider industry in several ways, for example:

- Sustainable practices often involve reducing waste and optimising production processes, which results in cost savings for the company. These cost savings will then be reinvested into further sustainability initiatives, driving innovation and inspiring other companies in the industry to follow suit.

- Companies prioritising sustainability can serve as role models for others in the industry. We can inspire other companies to take similar steps and work towards a more sustainable future by publicly sharing our sustainability goals and initiatives.

- Sustainability initiatives often involve collaborating with suppliers, customers, and other stakeholders. By engaging with these groups and sharing knowledge and best practices, companies can work together to develop more sustainable supply chains and practices across the industry.

It’s clear that our efforts as one company can have incredible effects on the wider industry. Because of this, we believe manufacturers should prioritise sustainability, which our Sustainability Statement aims to do; let’s take a closer look at what this is.

Our Sustainability Statement

At European Springs and Pressings, we understand our responsibility is to act in an environmentally-conscious manner and assist in protecting the planet for future generations. Our Sustainability Statement is a policy that will help us achieve this goal. It sets out our long-term strategy to:

- Reduce emissions

- Offset our carbon footprint

- Minimise the environmental impact of our operations

When collating our Sustainability Statement, we agreed that the term ‘sustainability’ is heavily focused on environmental issues but covers a much broader area than this. So, to make it easier to digest and simpler for our team to follow, we have broken down what sustainability means to European Springs into four distinct areas:

- Responsible Business. Ensure that our business partners meet the requirements in Code of Conduct.

- Responsible Production. Towards low carbon production with energy-efficient processes.

- Modern Employer. Be an attractive employer where employees are motivated and develop.

- Transparent Interaction with Stakeholders. Be a connected company through partnership. Team up and move faster.

This will allow us to focus on specific areas without becoming overwhelmed with changes to make and objectives to keep on top of. Within these areas are objectives; for example, we will find creative and sustainable solutions to customer needs to achieve Responsible Production.

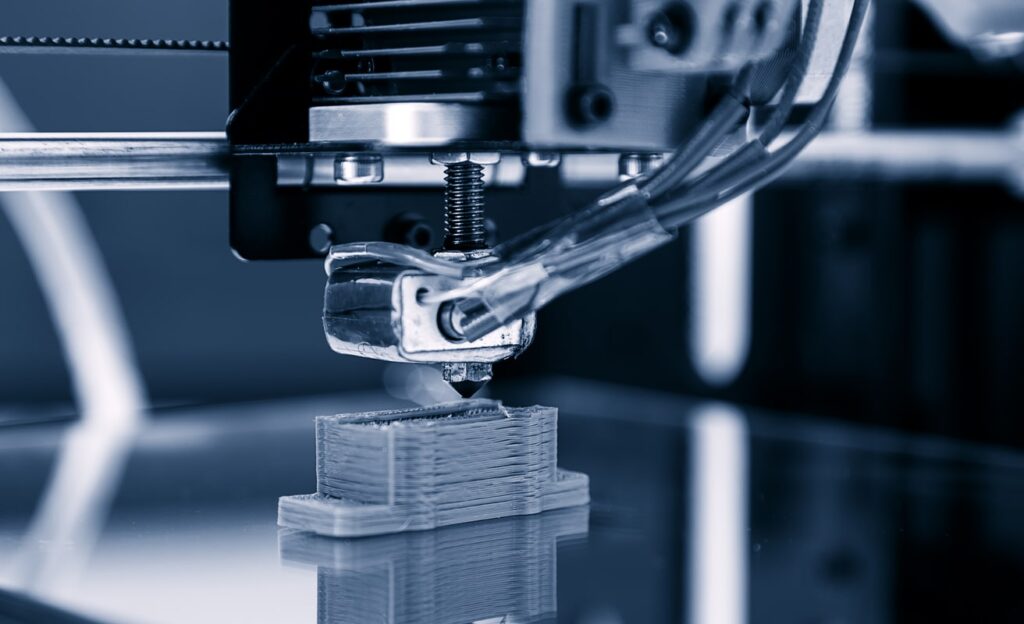

This could be within the spring design aspect of our company by suggesting alternative materials and finishes which are more sustainable.

Alternatively, it could be within the production of goods by maximising the technology available. We have spent decades testing new technology and perfecting the machines and processes we use at European Springs, so we must ensure that we’re making use of what we have to improve sustainability in our production processes.

What’s Next?

When setting objectives, monitoring their progress is crucial; otherwise, it is wasted time. We understand that implementing sustainable solutions is a slow process, so monitoring our progression as a company is key. The team plans to do this in many ways, such as taking audits on electricity and gas usage and the tonnage of raw materials and completed parts, including all the shipping and delivery information.

We are also encouraging our employees to take simple actions to ensure a more sustainable workplace, such as:

- Turning off lights when the room is not in use

- Keeping doors and windows closed when the central heating is in use

- Reporting broken or damaged machines, light fittings, gas pipes, air lines, or heating to allow for speedy repair

- Turning off any machines not in use, especially at the end of the working day

Sustainability goals should be a company-wide effort, which means every employee is responsible for contributing.

We’re excited to see the future regarding sustainability improvements within European Springs and the wider industry. To follow our progress, please check out our blog, where we post regularly.

The Aircraft Interiors Expo (AIX) is an annual event focused on the latest developments and innovations in aircraft interior design, technology, and equipment, so as

The Aircraft Interiors Expo (AIX) is an annual event focused on the latest developments and innovations in aircraft interior design, technology, and equipment, so as