Springs and Pressings in the Clean Energy Sector

Components in the clean energy sector play a crucial role in shaping a more sustainable future for power generation. Springs

Home › News & Updates

Components in the clean energy sector play a crucial role in shaping a more sustainable future for power generation. Springs

Safety is our top priority at European Springs and Pressings, and we are committed to ensuring our team is fully

The 10th to the 16th of February is National Apprenticeship Week, and here at European Springs and Pressings, we are

The performance and longevity of a spring depend not only on its quality but also on proper maintenance and regular

At European Springs and Pressings, we are dedicated not only to delivering high-quality products but also to ensuring they are

Springs play a crucial role across a wide range of industries, from supporting intricate mechanisms to powering heavy machinery. Perhaps

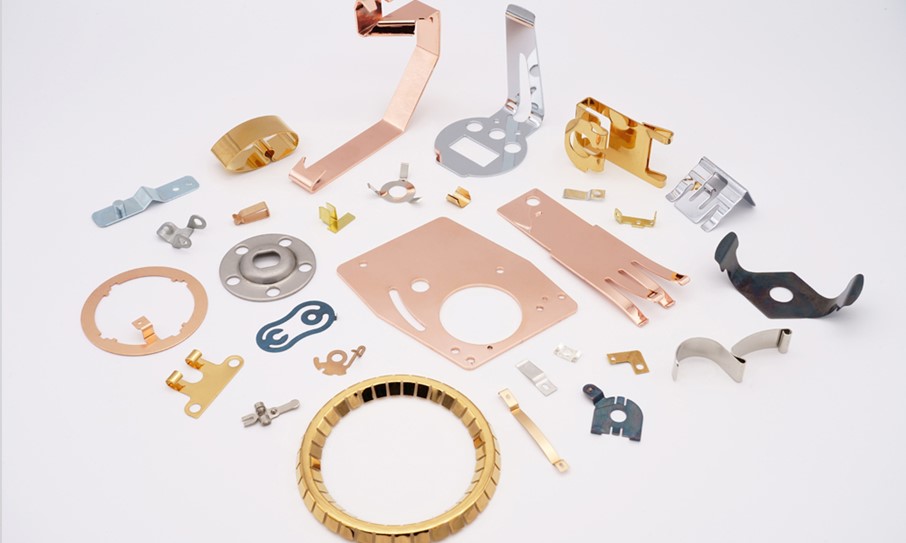

Melinex is a durable, heat-resistant material widely used in bespoke pressings and stampings across various industries. Its reliability and versatility

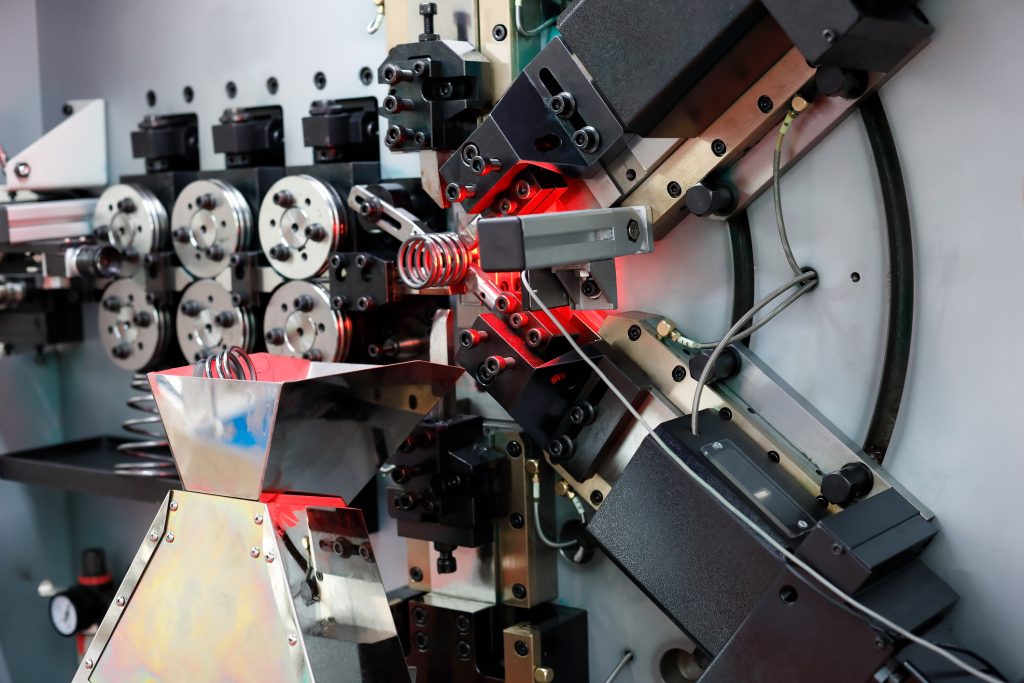

At European Springs and Pressings, we implement several procedures during our manufacturing process to ensure that the springs we create

At European Springs and Pressings, we prioritise high-quality and consistent manufacturing practices in all of our products. As expert spring

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital