Nestled in nanotechnology and microelectronics, springs and pressings are indispensable elements that enable the multiple functionalities that define our electronic devices and extend their durability. In this exploration, we take a closer look at the micro-sized power of springs and pressings, discovering their role in the world of electronics.

Electronics in Our Everyday Lives

In the fast-paced, tech-driven world we live in, electronics have woven themselves into the very fabric of our daily routine. From the moment we turn off our smartphone alarms in the morning to the number of steps counted by our smartwatches at the end of the day, we constantly connect, communicate, entertain, and engage within the frame of our digital companions.

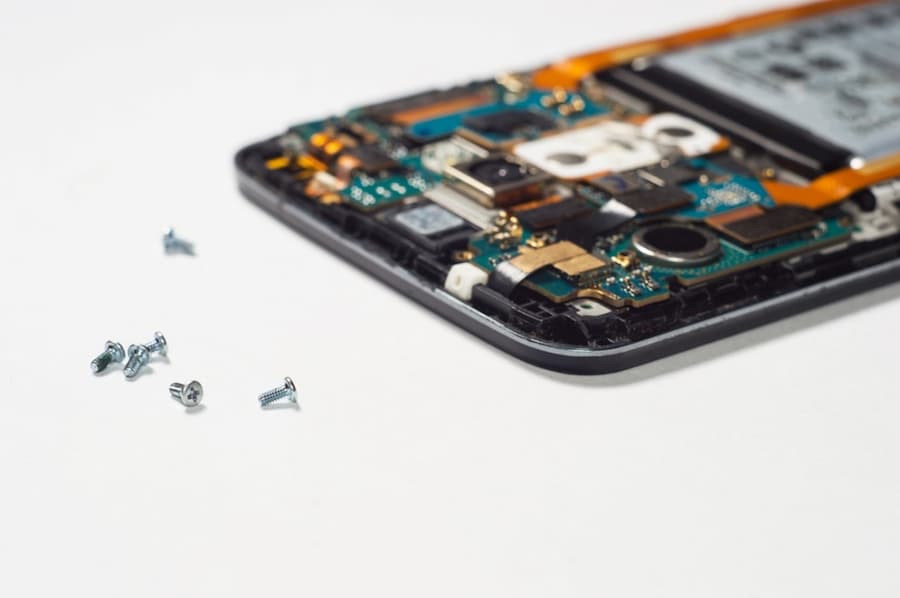

Behind the sleek facade of high-resolution screens and minimalist designs, a universe of complex engineering thrives. It is a fascinating labyrinth of printed circuit boards, clusters of transistors, rows of LEDs, and a multitude of capacitors and resistors that function synergistically.

In this system, springs and pressings may not immediately jump to mind when we think of our high-tech gadgets, yet they are the components that make the functionality of our devices possible. Springs are behind the tactile feedback of every button press on a gaming console; pressings help secure components, provide electrical contact, and even assist in heat dissipation. These elements don’t merely exist within the devices but are central to the way they work, bridging the gap between user and technology. In fact, springs and pressings are evolving in sync! Let’s delve into their specific applications.

Understanding Micro-Sized Springs and Pressings

Both micro-sized springs and pressings, despite their tiny size, carry a significant weight in the electronics industry. Although small, understanding these components, their nature, and functionality is fundamental.

Micro-Sized Springs: Flexing Their Power

Micro-sized springs, as their name suggests, are small but precisely designed components capable of storing and releasing mechanical energy due to their elastic properties. These springs come in numerous forms to suit different mechanical needs in various electronic devices. Be it compression springs used for resistance, torsion springs for rotational twists, or tension springs for tensile forces, these micro-sized springs are engineered to meet specific criteria of force and response under consistent or varying loads.

Pressings: Precision at Its Peak

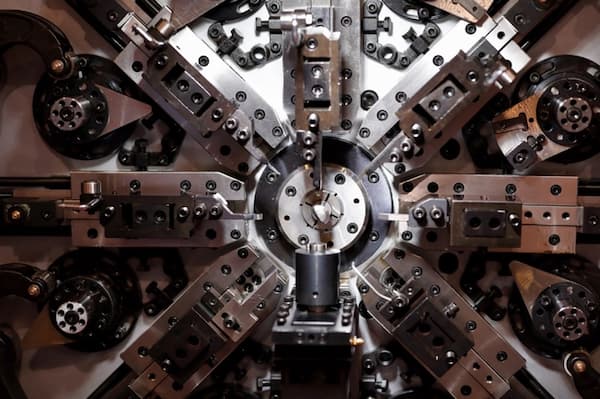

Pressings, on the other hand, are precision-crafted workhorses. Manufactured through one of the most reliable and efficient means of mass production, high-speed precision press stamping, they form complex shapes and structures with remarkable accuracy. They are commonly used in interfaces requiring robustness, electrical contact, superior thermal conduction, and even shielding against electromagnetic interference, like connectors, switches, shields, and even heat sinks.

Also, given their consistent production quality, they are central to maintaining the balance of quality and cost-efficiency in electronics manufacturing.

From Efficiency to Durability: the Contribution of Springs and Pressings

Imagine the zippy action of a camera shutter, the responsiveness of a game console button, or even the hinge of a laptop. Behind these simple mechanics, there are springs and pressings!

Micro-sized springs are no small players when it comes to smooth and controlled movement. They hold potential energy, like a coiled-up slinky, ready to spring into action whenever they’re needed. Whether it’s regulating the keys on a keyboard, activating a camera’s shutter, or controlling the retractable mechanism in pens, springs are hard at work, contributing greatly to an electronic device’s efficiency.

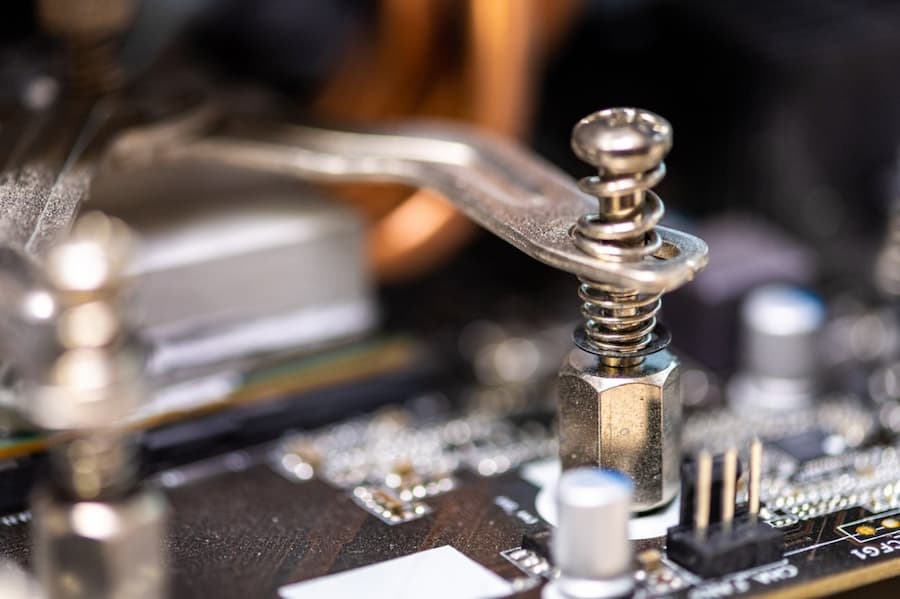

Metal pressings may not spring into action like springs, but they offer unyielding support and stability to electronic gadgets. They are the strong types that are moulded into precise shapes to fit just right and hold things together, adding strength to structures, serving as shields for sensitive elements, or even helping dissipate heat to cool things down. It’s like having a trusty sidekick, perfectly shaped and ready to support, adding lasting durability to our devices.

Applications in the Electronics Industry

Of course, the employment of micro-sized springs and pressings is not limited to consumer electronics. In the overall dynamic world of electronics, the need for precision, dependability, and adaptability is essential.

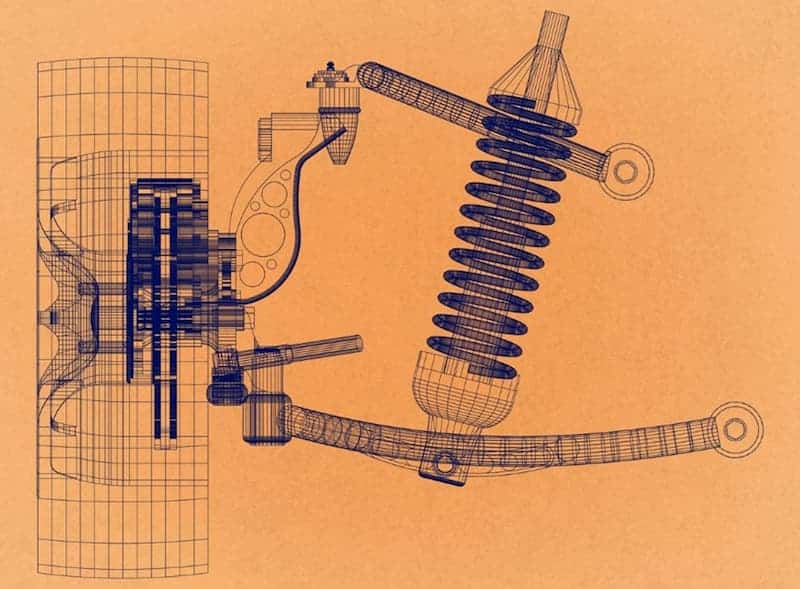

For example, the role of springs in healthcare offers the necessary level of accuracy and quality to allow medical devices to function with great efficiency, contributing to safe and effective patient care. In automotive, another sector that is evolving at lightning speed, springs and pressings’ contribution to automotive electronics makes sure that vehicles remain connected and secure as we drive toward a sustainable future. In aerospace, bespoke springs and pressings are critical in flight control systems, avionics, satellite communication devices, and military-grade equipment.

All in all, from the smallest gadgets that accompany us every day to the most advanced systems that propel us into the future, these tiny components never cease to improve the performance and reliability of those devices that continue to transform and enrich our lives.

European Springs & Pressings’ Unique Manufacturing Capabilities

At European Springs, as a leading pressing and small spring manufacturer, we are at the forefront of this micro-sized revolution. With a focus on quality and speed, we have positioned ourselves as a powerhouse in the production of micro-sized components for the electronics industry.

Contact us today to learn more about our services and products, and let us be your trusted partner in your next project.

In the healthcare industry, where precision and reliability are paramount, one might not immediately think of springs as fundamental players. However, when digging deeper, it is surprising to discover that the medical sector relies extensively on these minute, coiled components. Machines and tools employed by healthcare professionals worldwide often contain a spring or wire form of some kind. As a matter of fact, springs represent the backbone of medical equipment, ensuring the efficiency of instruments utilised in diagnosis, treatment, and patient care.

In the healthcare industry, where precision and reliability are paramount, one might not immediately think of springs as fundamental players. However, when digging deeper, it is surprising to discover that the medical sector relies extensively on these minute, coiled components. Machines and tools employed by healthcare professionals worldwide often contain a spring or wire form of some kind. As a matter of fact, springs represent the backbone of medical equipment, ensuring the efficiency of instruments utilised in diagnosis, treatment, and patient care. What Springs Are Commonly Used in the Medical Industry?

What Springs Are Commonly Used in the Medical Industry? Ventilators

Ventilators Precision in Diagnostics: Imaging Devices

Precision in Diagnostics: Imaging Devices

Springs and Pressings in Military Aircraft

Springs and Pressings in Military Aircraft