As a large proportion of the nation’s workforce heads back to their workplace, there are some businesses that have managed to hit the ground running, whilst others have struggled to find their feet. Whilst a lot of the issues faced by some businesses is down to the industry they operate within; other businesses have managed to thrive during this period due to forward planning and investing in the latest technology available.

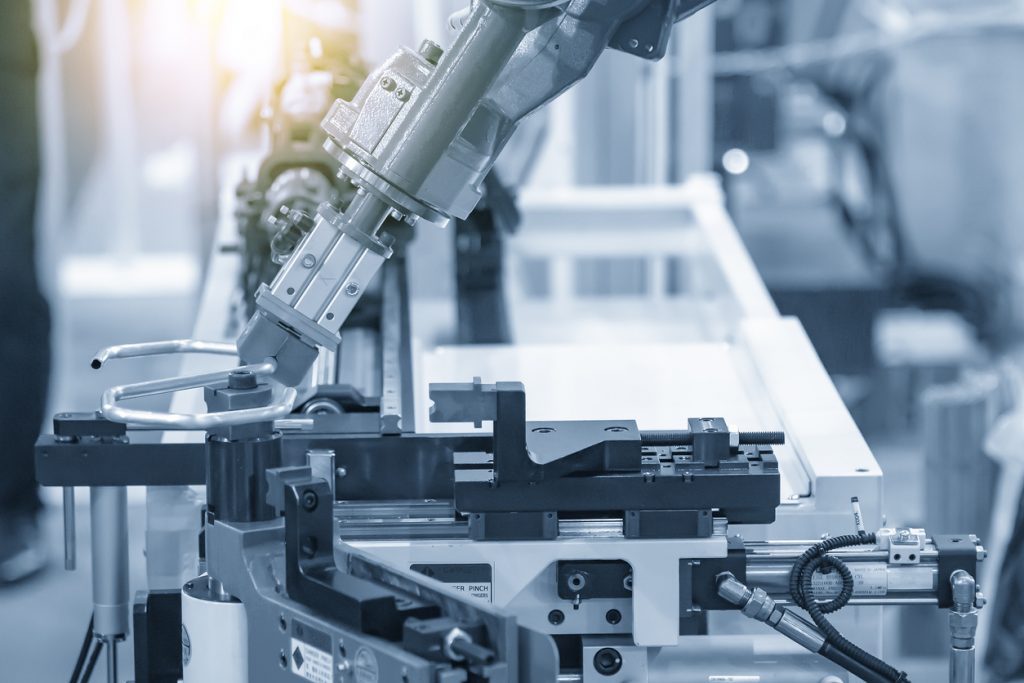

Here, we take a look at how innovation has helped businesses get back to work, placing particular focus on how automation has held the key to many manufacturing and engineering business’ success.

Benefits Of Automated Technology In Covid-19

Automated technology and other forms of innovations relating to the Internet of Things have catapulted manufacturing and engineering firms productivity levels in recent years, and this has showed little signs of slowing down despite the wide-spread effect of Covid-19 across the world.

Businesses that already have some automated technology installed into their current processes have found they have been able to continue operating at close to normal levels throughout the pandemic. This has meant that productivity levels haven’t been affected, and therefore there will be no backlog of orders as many other businesses come back to work in the coming weeks.

Some of the main benefits that automated technologies can bring to your business are:

- Uninterrupted productivity all year round

- Consistently more accurate part production and output

- Significantly lowered operating costs

- Improved worker safety

- Easy integration with existing processes and machines

- Better future planning

- Easily identify any inefficiencies in your current process

- Vastly reduced environmental footprint

At European Springs & Pressings, we have been operating at close to normal levels throughout the pandemic, as we have been extremely busy providing a whole host of vital components for respirators. This work wouldn’t have been possible without our continual investment in the latest and greatest technologies available in the springs and pressing world.

All of our investments have helped our team to continue working at close to optimum levels, whilst also maintaining social distancing measures at all times. With up-to-date and autonomous machines operating continually throughout the day, our staff have no need to come into close contact with each other with the current measures put in place by the government.

There is a similar theme for other businesses who have extensively invested in autonomous technology for their workforce, as this technology is meant to compliment employee skillsets and strengths, as it takes the pressure off staff to conduct some of the more mundane tasks that can be completed by a machine significantly quicker and more accurately.

Why Now Is The Right Time To Invest In New Projects

Now that you have some insight into how innovation has helped many businesses across the UK get back to work during the pandemic, you may be wondering if now is the right time for your business to begin investing in new projects to futureproof your company. Whilst it certainly can feel counterintuitive to begin investing in a new project right after getting back to work, there actually couldn’t be a better time to begin your innovation journey.

Here’s just a few reasons that now could well be the perfect time for you to invest in a new project:

- Many of your competitors will be in a similar position to your company, as they are trying to find their feet following the pandemic, so if you’re able to get a head start on innovating within your business, you could reap the rewards in the future.

- Several companies that produce the necessary components for innovative products will be looking for business, and with many companies not in a position to invest in new technology, they may be struggling to get much interest at this stage. This is a perfect opportunity for your business to come in and potentially negotiate a good deal on the implementation of new innovative technologies, as the provider will be desperate to get orders in.

- Rather than waiting months, or even years, to have your new project started on, you could see your new technologies installed within a matter of weeks during current circumstances. With a small number of orders likely placed, companies will be keen to get their products installed within your premises as soon as possible to show other interested parties they’re still open for business.

If you do require any further assistance when thinking about investing in new projects, then please feel free to get in touch with us to see how we could help you. As custom spring manufacturers with over 70 years of experience, we are capable of providing you with the right springs and pressings for your next project. Contact us today to begin discussing your vision for the next few years, and see how the team at European Springs & Pressings can help you with your next project.