Adaptability can be the key of your project and that is surely a feature of spring clips and wave springs. These are a great solution when a project faces restrictions in space or form but you don't want performance to be inferior. We offer a wide range of both products so we are positive our springs will fit your project.

Spring Clips

They can be found in a wide range of places: from electrical systems to cell-phone cases. Spring clips are generally u-shaped and can be made of various materials such as plastic, wood or steel. They are used to fasten two moving parts or to hold something in place. Their grip is so strong they can resist tension, movement and even dampen vibration. They are also one of the most cost-effective types of springs as they can substitute the combination of nut, bolt and a washer when used to attach components together. At European Springs we can design spring clips to meet your specific requirements. We create them with open and closed ends and we can add extra features such as holes for fitting screws and holes.

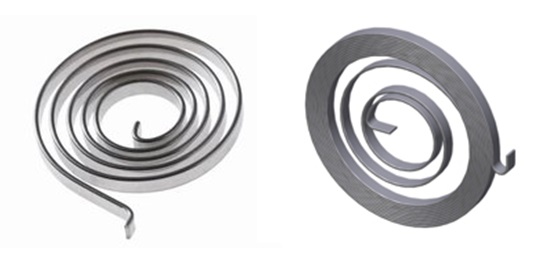

Wave Springs

The versatility of these springs is evident if we look at their practical uses: aerospace, automotive, medical and oil and gas industries. They are made of flat spring metal and have a multi-coil waved framework. These springs are the perfect choice when just small areas of space are available, as they reduce up to 50% in height and length of conventional round wire springs. That is why they can replace coils, which usually demand more space. This also means less material is required to make them, so their production is very efficient. We manufacture our wave springs to be compact but if you want any radial specification don't hesitate to contact us and we will be glad to discuss your project's needs.

Finding the perfect fit

Spring clips and wave springs are used when the maximum flexibility is needed. Take a look at our extensive stock catalogue ; we are sure you will find your perfect fit. And if that is not the case, contact our team of experts to let them know what your project requires, so we can provide you with exactly what you need. We are also happy to discuss any new design you might want to add to our existing products.

European Springs are a leader in spring production and manufacture in Europe, so we are positive we can meet the expectations of your project. Feel free to call us on 0208 663 1800 with any enquiry, and follow us on Facebook and Twitter to keep updated with the spring industry's news.

European Springs