The Role of Melinex in Precision Tooling and Pressing Applications

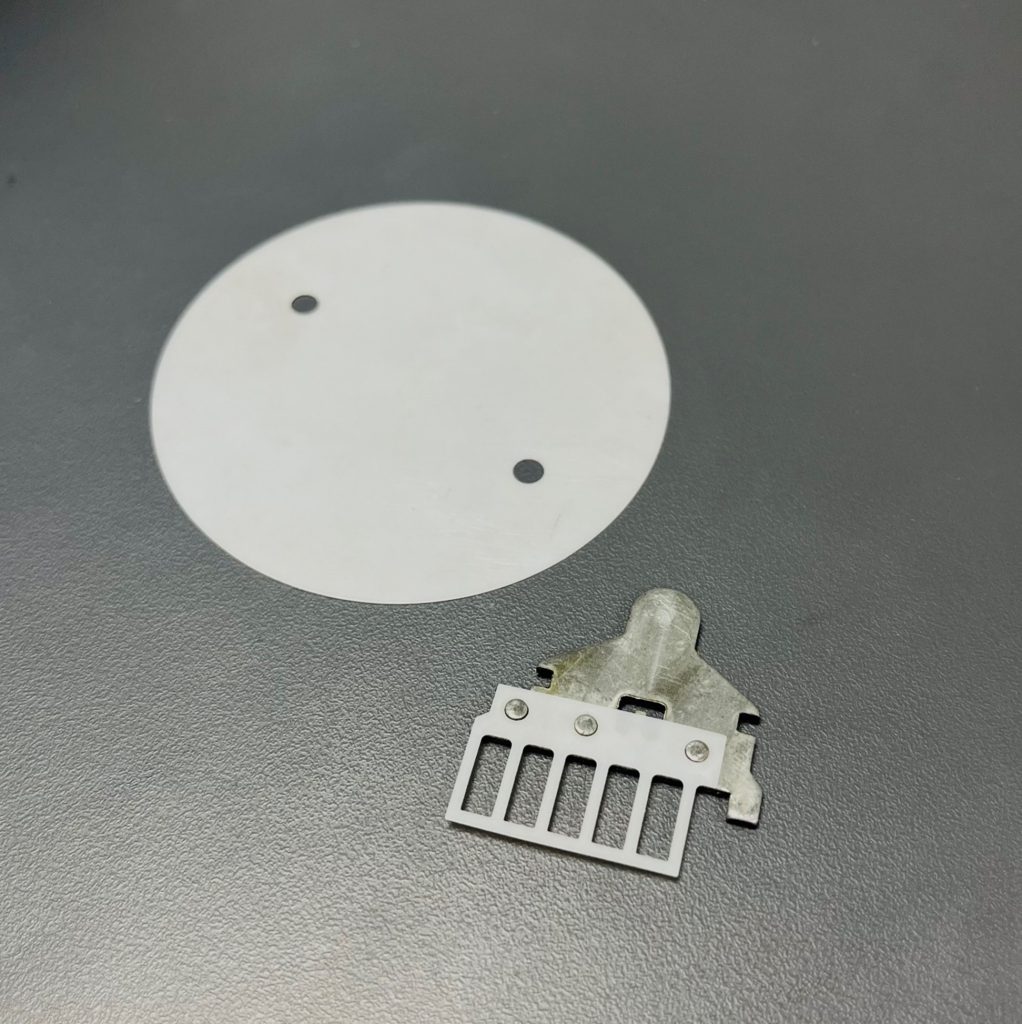

Melinex is a durable, heat-resistant material widely used in bespoke pressings and stampings across various industries. Its reliability and versatility make it a popular choice for a number of different applications, such as an insulating material, or for packaging and labelling.

In this blog, we’ll explore what Melinex is, how it’s used, and why we think it’s ideal for precision tooling and pressing.

What is Melinex Film?

Melinex is a biaxially oriented specialty polyester film developed by Mylar® Specialty Films (formerly DuPont Teijin Films™). Available in a variety of types—such as super clear, slightly hazy, hazy, translucent matte, opaque white, and heat-stabilised—Melinex can be tailored to suit the users’ specific needs. Its general appearance is clear and glossy, but this varies depending on the chosen finish.

Melinex films are flexible and high-quality, with an excellent resistance to heat. Polyester films such as these are frequently used in the automotive, electronic, medical, and electrical industries. Whilst Melinex can be used for pressings and stampings, this material is also used in labels, die-cut parts, packaging, and insulation. It is a versatile and reliable material that offers some superior benefits to other plastic films.

What are the Benefits of Using Melinex Film?

There are many reasons why our customers choose to use Melinex Film in the manufacturing of their bespoke stamping or pressing. Here are a few reasons why Melinex stands out as an excellent material choice:

Reduces Wear on Tools

Melinex is known for its ability to reduce wear on tooling equipment. It is a very durable material, meaning that your stampings and pressings stay in a pristine condition for longer. This reduces the need for regular replacement or maintenance, helping to save costs in the long term.

Supports Efficiency in Manufacturing Setups

Melinex has excellent dimensional stability, meaning that it maintains its size and shape under a variety of conditions. This allows for smoother manufacturing setups, as it is easier to handle and process the material. Melinex is also very flexible, which can furthermore assist in the manufacturing process. Its flexibility causes quicker setup times, reducing cycle times and increasing overall efficiency.

Tool Designs that Need Tight Tolerances

When we’re crafting precision tooling, materials that are able to maintain tight tolerances provide benefits to the overall manufacturing process. When using Melinex in pressing and stamping applications, we’re able to produce components accurately, so that the final product meets your expectations and specifications. This is especially important in areas such as the electronic and automotive industries, where even the slightest dimensional variation can cause severe functionality issues.

Heat Resistance

Melinex is renowned for its heat resistance, making it an ideal material to be used in pressings and stampings that are exposed to high temperatures. Melinex can operate at a temperature range from -70°C up to 150°C, and special variations of the film can be made to be especially heat-optimised. This wide operational temperature range means that Melinex has a wide application range, and may be the suitable choice where other materials might distort or break down.

Uses of Melinex Film

In addition to its use in stampings and pressings, Melinex film has a wide range of uses across different applications because of its versatile and durable properties. Here are some of the main industries that utilise Melinex Film:

- Automotive: The automotive industry has a high number of uses for Melinex, especially in areas where high heat resistance is needed. It’s commonly found in components like insulation, seals, and gaskets.

- Packaging: Melinex is frequently used in clear packaging, particularly within the food and beverage industry due to some of its variations being compliant with food safety regulations. Its flexibility allows it to be produced in specific shapes, protecting items without releasing any harmful chemicals.

- Signage and Display: Due to its high performance and anti-shrinking capabilities, Melinex is found in several signage and display applications. This applies to outdoor signage also, due to its ability to withstand different temperatures and environmental conditions.

- Electronics: Melinex is used in electronics for its ability to insulate and protect certain electronic components. It is found in circuits and printed electronics due to its capability in holding its original form and chemical makeup, even when it’s exposed to wiring or heat-producing components. This is especially important because it can alleviate concerns about melting, releasing fumes, or toxic materials

Melinex in Precision Tooling and Pressing Applications

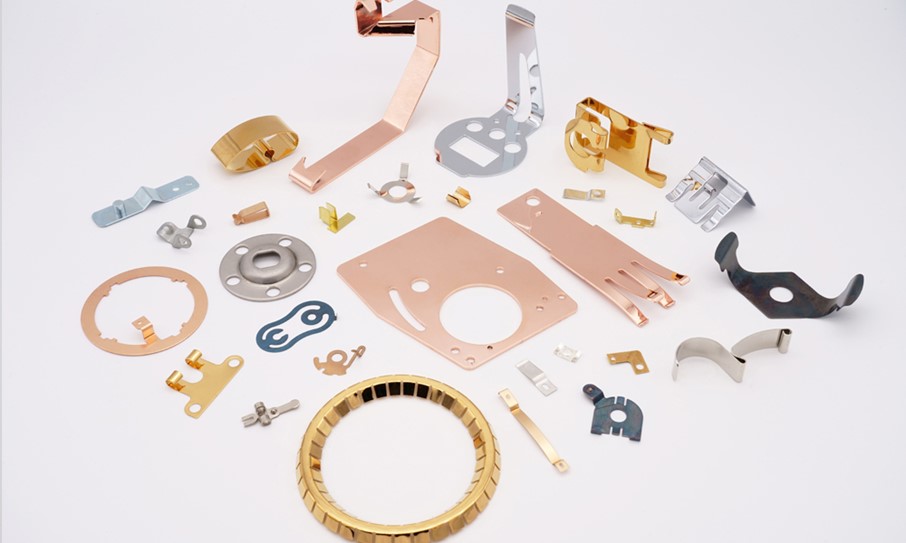

At European Springs and Pressings, we offer Melinex as a material for our pressings and stampings, in addition to other high-quality materials like metal strips, carbon and stainless steels, and superalloy. Melinex offers a selection of benefits including flexibility, heat-resistance, and durability, making it suitable for a number of applications and industries. To learn more about our bespoke stampings and pressings and the materials we utilise, get in touch to speak with a member of our expert team.