The Importance of Stress Relieving in Spring and Pressing Manufacturing

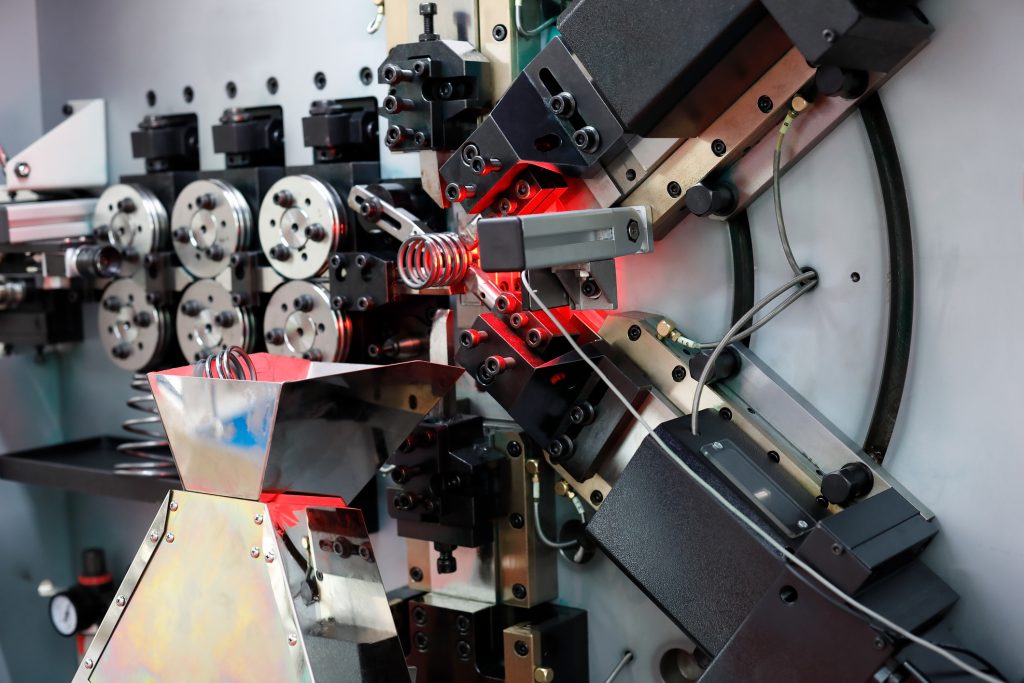

At European Springs and Pressings, we implement several procedures during our manufacturing process to ensure that the springs we create are of the highest quality and durability. One way we help to guarantee the longevity of our springs and pressings is through surface treatments such as stress relieving.

Continue reading to learn more about stress relieving, including what exactly it entails, how it compares to other forms of heat treatment and how it can elevate the quality of a spring or pressing.

What is Stress Relieving in Springs and Pressings?

Stress relieving is a process used within spring manufacturing that helps the spring or pressing last longer and makes it more reliable. It is a form of heat treatment in which the spring undergoes controlled heating and cooling processes so that newly coiled springs can become more malleable without the material being completely transformed. This needs to be a controlled process because if the spring or pressing is heated or cooled too quickly or slowly, then it is subject to breaking.

As cooling processes occur, molecules are repositioned, so stress-relieved springs may look the same on the outside, but their internal makeup will be different. There is more than one type of stress relief for industrial springs. In addition to heated stress relief, there is also induction stress relief, which involves running an electric current through the springs, which still heats the spring to an optimal temperature. This method allows each spring to be stress relieved whilst keeping its place and orientation, producing a similar effect to the heat-treated spring relief.

Stress Relieving versus Other Heat Treatments

Even though stress relieving employs heat treatment principles, it is generally not regarded as a form of heat treatment. The processes, methods, and final results of spring relieving are different from those of other heat treatments. For instance, a commonly used heat treatment is quenching, where the heated spring material is placed into oil, water, polymer or another quenching source. This is particularly useful for springs and pressings that need a high level of hardness. Moreover, tempering is a form of treatment that can be used after quenching, which reheats the quenched material to a lower temperature, improving strength and hardness.

The treatment and temperature applied to the spring will generally depend on its material, type, and application. Most steel springs are heated to between 350°C and 650°C, with copper alloys needing lower temperatures, and nickel alloys needing higher ones. This will also impact the time needed for the stress relief process, with thicker springs needing more time than those of a thinner construction. The environment in which stress relief takes place is important, to avoid causing rust or damage to the spring or pressing.

Why is Stress Relieving Beneficial for Springs?

Springs are used repeatedly and often must withstand heavy loads. Introducing stress relief into the manufacturing process helps to improve a spring’s lifespan and prevent it from cracking under pressure. Without stress relief, springs are more likely to change and contort over time, reducing their overall efficiency as a result. Even though the molecules inside the spring are more malleable, stress relieving does not change the hardness or material structure of the spring, so the springs still look and work the same. In addition, by increasing the strength and durability of the spring, stress relieving can be a cost-efficient measure as it’s less likely that the springs will need replacing.

How does Stress Relieving Impact Spring and Pressing Quality?

Ultimately, stress relieving improves the spring and pressing quality and gives them longer-lasting capabilities. This process reduces the risk of failure or breakages over time, so that your mechanisms and machines are reliable. The shape of a spring can change during the stress-relieving process, mostly in its outer diameter. Stress relieving can decrease the overall diameter of a spring. However, this is dependent on the material, as with stainless steel springs, the diameter will actually increase. We will account for any changes such as these during our manufacturing process, and even though this initial change in shape may occur, in the long term, springs will be less likely to deform.

When carrying out stress relief on your springs, we will choose the correct heat treatment for the material and specifications to ensure that the end result is perfect. Stress relieving is a crucial step to take within spring and pressing production that results in reliable, durable, and high-quality springs. We offer a range of surface treatments for our springs and pressings that can help them perform better for longer. To learn more about our stress relieving and other surface treatment options, then feel free to contact us.