The Fourth Industrial Revolution: Industry 4.0

Industry 4.0 is the buzzword of the moment, but there is good reason that so many within the manufacturing industry are constantly talking about it. Whilst everyone is talking about why you should implement Industry 4.0 technologies into your business, you may be wondering exactly what Industry 4.0 is, and how can it benefit your business.

In this article, we take a look at what Industry 4.0 actually is and highlight some of the main reasons that you may want to consider implementing it within your business, sooner rather than later.

What Is Industry 4.0?

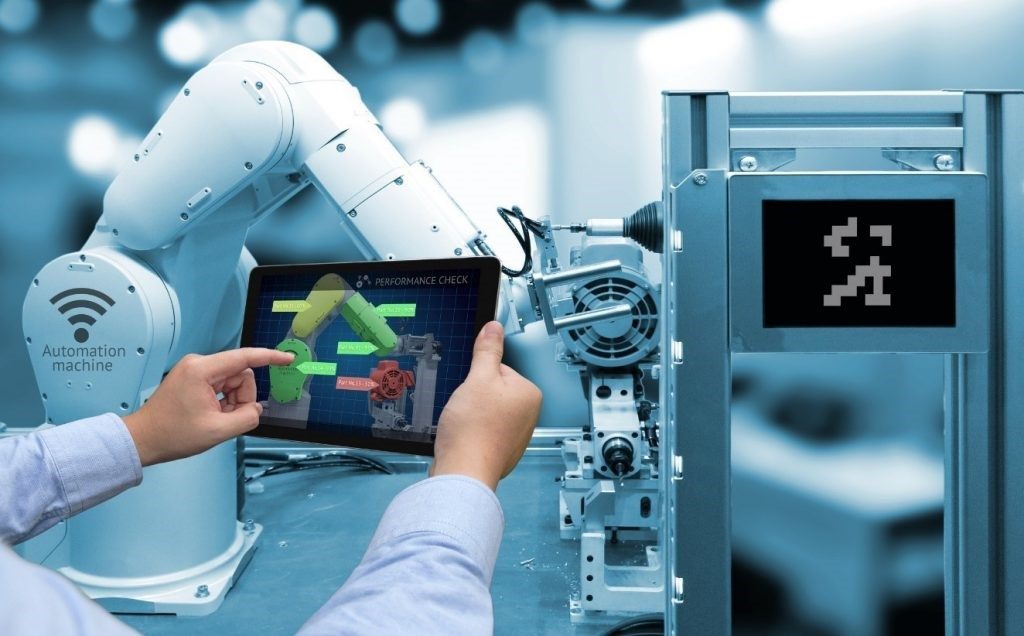

In simple terms Industry 4.0 is the fourth industrial revolution, which has seen the use of smart factories, using connected machines and intelligent robots alongside more traditional manufacturing technologies.

There’s no denying it, we are currently in the midst of a digital revolution of how products are produced in the manufacturing industry, with a real focus being placed on smart, autonomous systems that are fuelled by data and machine learning.

What Is The Difference Between Industry 3.0 and 4.0?

Industry 3.0 came about after computers were introduced, and whilst computers have completely revolutionised the way in which businesses work across the world, their initial impact was more troublesome than helpful. However, with a shift from Industry 3.0 to 4.0 well underway, it’s fair to say that the transition has been far more seamless, with the computers now commonly used in manufacturing all being programmed to communicate with one another, allowing them to ultimately make decisions without human intervention.

The Internet of Things and Internet of Systems make Industry 4.0 possible, and as a result of the infrastructure now in place, smart machines are only getting smarter as they get access to an ever-increasing amount of data. As machines gain access to more data, this will result in manufacturing businesses across the world having access to equipment that is capable of increasing productivity, efficiency and decreasing product waste.

Should My Business Invest in Industry 4.0?

Industry 4.0 has already had a profound effect on the manufacturing industry, with many businesses around the world integrating some form of connected machinery or intelligent robots into their manufacturing processes. But there are still a whole host of businesses who are yet to properly integrate smart technologies into their day to day processes; and whilst there are a number of completely valid reasons for this, it is well worth highlighting some of the major benefits that Industry 4.0 can bring to any manufacturing business.

Here are just some of the benefits of incorporating Industry 4.0 into your workplace as soon as possible:

Increased Productivity and Efficiency

Industry 4.0 technologies enable your business and workers to do an awful lot more with significantly less machinery and equipment required. By incorporating smart technologies into your business, you can produce more products in a shorter amount of time, allowing you to meet consumer demand.

In terms of efficiency, smart technologies are capable of automatic track and trace processes and automated reporting, which frees up even more of your employee’s time to ensure your processes are as slick as possible throughout your business.

Along with this, it’s also worth noting that your production lines will experience a significant cut in down times, as machine monitoring enables your employees to intervene as soon as possible if any problems do begin to arise.

Reduce Costs

With increased productivity and efficiency throughout your business, you can be sure you will reap the benefits in terms of cutting costs too. Whilst there are upfront costs you will inevitably face when implementing Industry 4.0 technologies, it’s fair to say that you will see a drastic fall in your overall costs as a result of Industry 4.0 equipment, such as automated technology, systems integration and data management systems.

You may be wondering exactly where the cost reductions will be coming from when it comes to smart technologies: here are just a few examples of potential cost savings:

- Significantly faster manufacturing will increase sales

- Vastly reduced material and product wastage, thanks to improved technology

- Reduced machine downtime ensures your products are consistently being produced

- Reduced operating costs with equipment operating at a far more efficient level

- Virtually no quality issues with products, meaning fewer returns

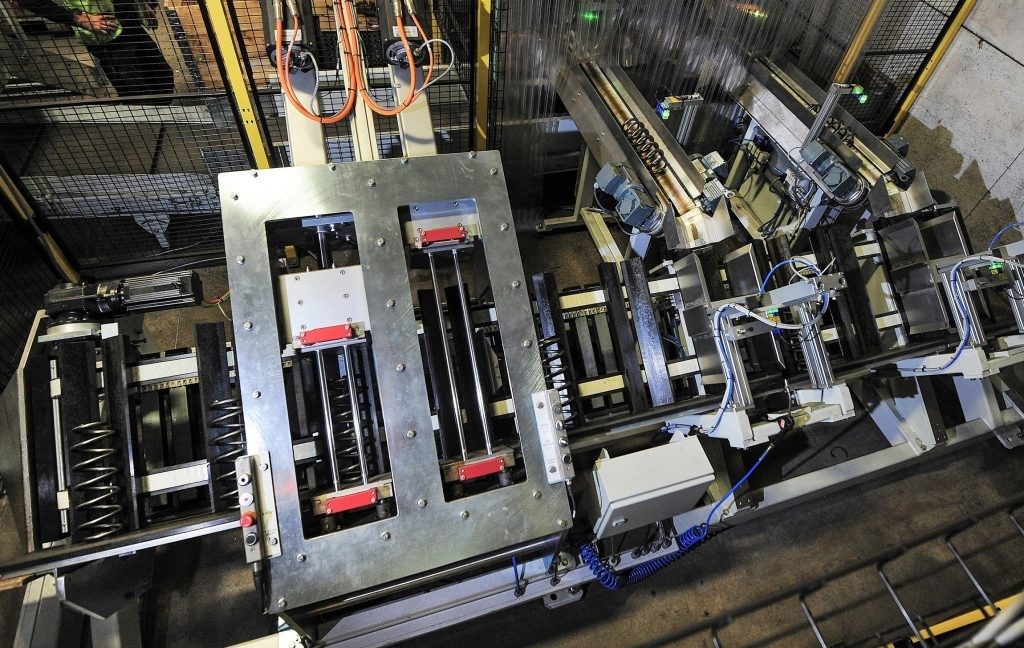

Whilst it’s fair to say there are a whole host of benefits your business will want to take advantage of, it’s worth noting that these changes will not happen overnight. Properly implementing industry 4.0 technologies into your business takes months of planning and identifying the right types of smart technology that will work for your company. But the team here at European Springs can assure you it is well worth the time and effort, as just last year we invested in an automated pre-stressing machine which enhanced our capabilities as custom spring manufacturers. Since upgrading our equipment, we have seen an upturn in productivity, allowing us to better serve our valued customers.