Objects that Couldn’t Be Made Prior to 3D Printing: Everything Else

Here at European Springs, we’re always on the lookout for new engineering feats to celebrate. With the sector being at the core of our innovation and creation of die springs, we like to see what other engineers have been up to!

So far, in our series about objects that couldn’t be made prior to 3D printing we’ve analysed transport and body parts. For the final instalment, we’re going to lump together the rest of the mindboggling innovations that have arisen to give you an overview of everything else!

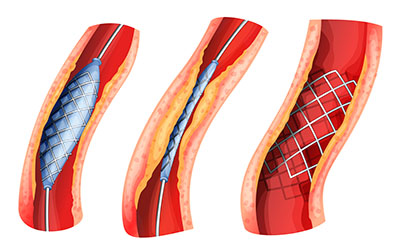

Surgical Stents

Although stents have been around for some time, 3D printing has made them more versatile and customisable and at a much lower cost. For those who aren’t quite sure what a stent is, it’s a miniscule tube that surgeons can place in blood vessels or arteries to hold them open and allow them to function properly.

Prior to 3D printing, stents were made from mesh. However, now it is possible to create them from flexible polymers that can be dissolved safely into the bloodstream within a couple of years.

To give an example of how this has proven to be highly successful, doctors at the University of Michigan implanted a 3D printed stent above an infant boys’ lung to open his airway and help him to breathe. The technology available allowed doctors to create a customised stent that would fit the little boy’s anatomy.

Other doctors have used 3D printing to create models of a patient’s heart to know whether stents will fit and where to put them.

Buckyballs

Prior to 3D printing, creating complex models of molecules was more than likely a result of an arts and crafts project. However, teachers across the world can now rejoice because 3D printers are capable of producing big, accurate models of molecules. Plastic models could have been made with injection moulding, but nothing as complex as the Buckminsterfullerene molecule aka a Buckyball.

Furthermore, 3D printing isn’t just limited to creating models; it can actually help to make the molecules themselves. Dr Martin Burke and his team at the University of Illinois created a machine that fuses small, organic molecules and then prints billions of combinations. In the future this could be used to speed up the testing of new drugs.

Moulds of Your Jaw

For many years, people have had to endure having a cement-like substance in their mouth so that their dentist could accurately see what their jaw looks like. However, 3D printing has now allowed dentist’s to view inside a patient’s mouth through Computer Aided Design and 3D printing. It’s good news all round!

To keep up to date with our latest news about the engineering sector, follow us on Twitter or like us on Facebook. Alternatively, get in touch with a member of our friendly and expert team if you have any questions about our springs by calling 0208 663 1800.

European Springs