Manufacturing Trends to Look Out For in 2019

The manufacturing industry is notorious for being extremely fast-paced, so failing to keep up with the changes can mean your business falls behind competitors in the blink of an eye. As 2019 approaches us at a blistering pace, the manufacturing industry is gearing up for yet another period of change.

In this article, we will take a look at some of the top trends to look out for in 2019, keeping you ahead of the game and, of course, your competitors.

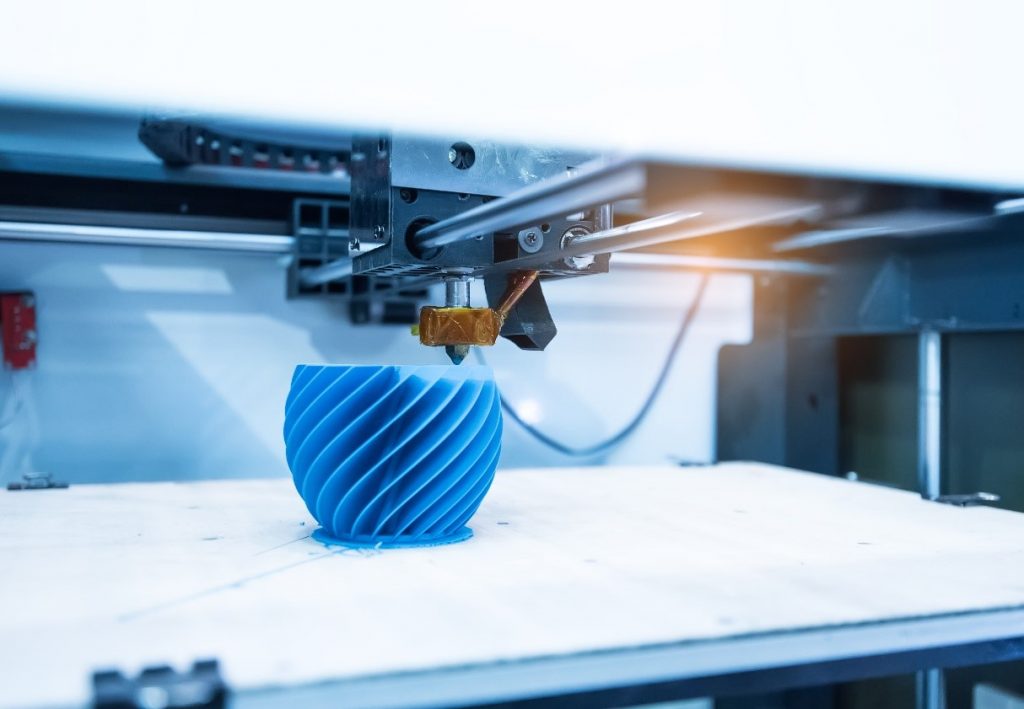

3D Printing

Whilst 3D printing has been around for a while now, this form of manufacturing has really started to take off throughout 2018 and looks set to be a big part of 2019’s manufacturing trends across the globe. This technology has the power to completely revolutionise the way manufacturing works.

In 2018, we started to see a significant rise in the number of companies using 3D printing due to the increased output it offers, alongside smaller cost implications and less wastage produced.

We even saw 3D printing being used as a solution to build homes from scratch; we realise this sounds like something out of a futuristic film, but it really works. Check out the video below:

Whilst the current 3D technology available is certainly capable of cutting costs and build time of products drastically, 2019 looks set to build on this technology, whilst making it more affordable and accessible for businesses.

Augmented Reality

Augmented reality feels like it has been around for many years now, but in truth, AR is still in its infancy and is set to completely revolutionise all our lives. Whilst many still associate AR with gaming and entertainment, in actual fact, it has the capability of being used in almost any industry.

In terms of the manufacturing industry, it’s no secret that jobs within the sector can be dangerous if you are inexperienced. AR could provide a safe alternative to on-the-job training for apprentices, new starters or any member of staff looking to upskill. By using AR in the training process the risk of injury is reduced massively, and the employee can learn at a pace that suits them, without being put in any considerable danger.

Away from training, AR is also being trialed as a simulator for potential designs and products, without the need for building physical prototypes. This obviously brings about many benefits for a manufacturer, from reduced manufacturing costs to ironing out any potential issues before investing further in a product and therefore reducing waste.

Expect to see AR become more widely used throughout 2019 as more businesses begin to understand the benefits this technology brings.

Industrial Internet of Things (IIoT)

It’s clear to see that the manufacturing industry is undergoing a digital revolution and has been for some time. We are confident 2019 will continue the trend of IIoT being implemented on a larger scale, across the world.

A huge emphasis has been placed on connecting the physical and digital world throughout the past few years, as a large amount of data is seen to be ‘trapped’ in factory-floor machinery. Fully capturing and utilising this data to better understand and improve operations, reduce costs and make a workplace safer is what we can expect to start seeing more frequently in 2019.

Along with this, 2019 looks set to increase the prominence of interconnected devices, intuitively communicating together to potentially learn from each other. The aim of this is to decrease the waste produced and improve the efficiency of the manufacturing process within a business.

As an expert spring manufacturer, we are looking forward to seeing what trends 2019 brings for the world of manufacturing. We can guarantee that the team at European Springs will be right at the forefront of any innovations 2019 brings, as we strive to provide our customers with the very best bespoke pressings on the market.