Tension Spring Manufacturers

European Springs and Pressings have over 70 years’ experience and are among the UK’s leading tension (also referred to as extension) spring manufacturers.

We are your premier partner for high-quality tension spring manufacture and supply needs. With decades of experience, and commitment to excellence, we have developed a vast range of tension springs for countless applications and sectors over the years.

Providing Both Custom Tension Springs & High-Quality Stock Solutions

European Springs & Pressings offer both custom spring solutions as well as stock extension springs. Depending on your specific needs, you may find one of these solutions is better for you.

A Customised Solution

Often our customers have a specific spring application in mind that necessitates the design and manufacture of a bespoke solution. Through our tension spring design services, we offer unique solutions with specific design and material selection considerations.

Our experienced engineers utilise state-of-the-art CAD CAM systems to bring your ideas to life with precision and efficiency. Taking into account the environment, stresses, life-cycle requirements and many other factors, we can assist in the design of custom tension springs that are precisely optimised for their intended use. European Springs is accredited with ISO 9001:2015, guaranteeing you quality springs throughout the manufacturing process.

Stock Extension Springs

As part of the internationally renowned Lesjoforsab Group, we are also extension spring suppliers of off-the-shelf stock spring solutions. Within the wire springs catalogue, you will find stock for unalloyed steel extension springs, manufactured from cold-drawn steel for high-static load or low-dynamic load applications (EN 10270-1-SH). Stainless steel tension springs are also available (EN 10270-3-1.4310). Within the catalogue, there is information about maximum load length, operating temperatures and spring cycles.

We are confident you will find what you’re looking for in a stock spring solution, however, if you can’t find what you need, please call us on +44 (0) 208 663 1800 for more information, or to request a quote. Our team are ready to help you design a tension spring made to your specific requirements.

Experienced Tension Spring Manufacturers

At European Springs, we pride ourselves on being reliable tension spring manufacturers that provide our clients with a wide range of dimensions to fit all requirements.

We can create springs with dimensions of as little as 0.1mm right through to 26mm. We can produce springs by using either a hot or cold coiling process with both steel and stainless steel. The end types we provide vary from coiled loops or hooks to screw-in fixture attachments. Popular choices include the half hook, extended hook and screw plug.

Comprehensive Services & Dedicated Customer Support

In addition to tension spring manufacturing, we offer a range of additional services to streamline your project requirements. From laser cutting for R&D testing to heat-treatment and assembly services, we provide end-to-end solutions to meet your needs.

You can find out more about our surface treatments, sub-assembly services and prototyping capabilities by browsing our website.

As expert tension spring manufacturers, European Springs & Pressings offer an array of other spring types, such as compression springs and torsion springs, all crafted by professional spring manufacturers.

At European Springs, your satisfaction is our top priority. Our dedicated team is committed to providing personalised assistance and support throughout your experience with us. From initial consultation to after-sales support, we ensure a seamless and hassle-free experience.

Frequently Asked Tension Spring Questions:

What Are Tension Springs?

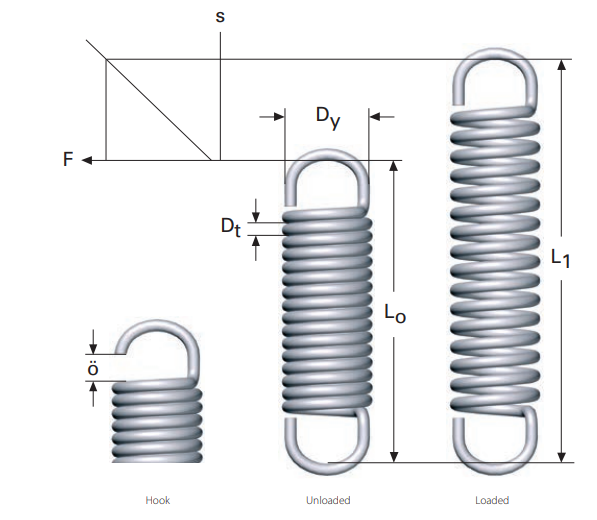

Tension springs, alternatively known as extension springs or coil tension springs, are tightly wound coils engineered to function under tension force. Typically featuring loops or hooks at each end for attachment, these springs are designed to store and release energy when subjected to external forces.

These springs find widespread applications in various settings, from counterbalancing garage doors to farm machinery and trampolines. Their primary role is to harness external force, utilising the stored energy within the coil to draw components together, thus reverting to their original configuration. Due to their function, tension springs are tightly wound and closely coiled at rest.

How Do Tension Springs Operate?

Tension springs serve to connect two components, bringing them together when there’s a tendency for separation. When subjected to a load or force, the spring elongates to a specific length, absorbing energy and generating resistance against the pulling force. In their relaxed state, the coils of the spring are in contact with each other.

Upon separation of the components, typically from opposing directions, the spring strives to maintain cohesion, exhibiting spring action until the force is counteracted, allowing it to return to its original state.

Many high-tension springs are wound with initial tension, which is the force holding the spring coils compacted together. The measurement of initial tension represents the load required to overcome the internal force and initiate coil separation.

What Are the Industrial Applications of Tension Springs?

Tension springs find utility across a broad spectrum of industries, including:

- Rail

- Agriculture

- Oil and gas

- Aerospace

- And numerous others.

As tension springs suppliers, we manufacture these springs in a variety of sizes to accommodate diverse applications. Here are some common uses:

- Trampolines

- Automotive components (interior and exterior)

- Garage door mechanisms

- Agricultural equipment

- Pliers

- Medical devices like stretchers and surgical lights